Parametric Analysis and Parameter Inversion of the Crystal Plasticity Constitutive Model for as-Cast TiZrNbV Refractory High Entropy Alloys

-

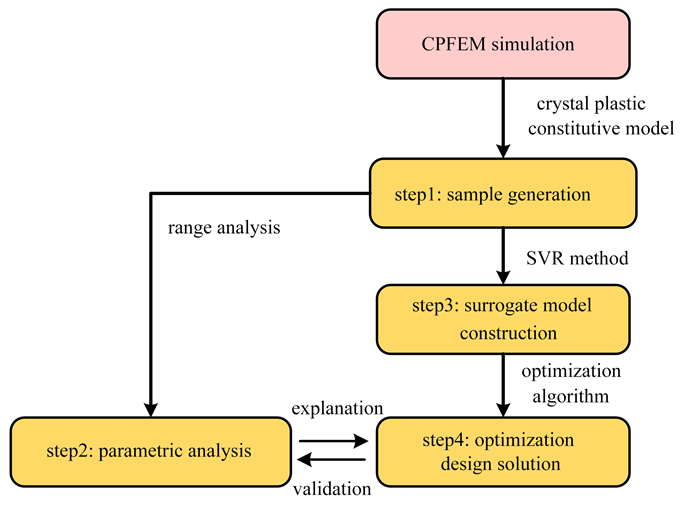

摘要: 难熔高熵合金因其卓越的力学性能而备受关注,但其细观特征行为对其宏观力学行为的影响尚未被充分理解. 随着对材料细观力学行为研究需求的增加,晶体塑性有限元方法已成为揭示晶体材料细观机制的关键工具. 由于晶体塑性本构模型包含众多复杂参数,深入分析这些参数对于理解合金的细观力学行为至关重要. 研究中采用的晶体塑性本构模型考虑了Peierls应力,这一因素能够反映材料的短程势垒,从而更准确地模拟材料的应变率行为. 通过试验设计和极差分析,识别了影响合金力学性能的关键本构参数. 单因素分析明确了关键参数对材料力学特性的具体影响. 在参数反演方面,提出了一种基于优化设计的参数反演方法,该方法结合支持向量回归法和优化算法,能够有效地从宏观力学测试数据中反演出晶体塑性本构参数. 针对铸态TiZrNbV合金,成功反演出一组最优参数,仿真与试验的一致性验证了该方法的有效性. 研究为难熔高熵合金的力学行为预测、材料设计以及性能优化提供了有力的支撑.Abstract: Refractory high-entropy alloys (RHEAs) have attracted considerable attention due to their outstanding mechanical properties. However, the influence of their microstructural behavior on macroscopic mechanical performance remains poorly understood. With the increase of study on material micromechanical behaviors, the crystal plasticity finite element methods become essential tools for uncovering the underlying mechanisms of crystalline materials. Since crystal plasticity constitutive models involve numerous complex parameters, a thorough analysis of these parameters is critical for a deeper understanding of the micromechanical behaviors of alloys. The crystal plasticity model used in this study incorporates the Peierls stress, which accounts for the short-range potential barriers of the material, thereby enabling a more accurate simulation of its strain-rate behavior. Through experimental design and range analysis, the key constitutive parameters affecting the alloy's mechanical properties were identified. Univariate analysis was then employed to clarify the specific effects of these critical parameters on the mechanical characteristics of the material. For parameter inversion, an optimization-based approach was developed, combining the support vector regression with optimization algorithms. This method effectively inverts crystal plasticity constitutive parameters from macroscopic mechanical testing data. For the cast TiZrNbV alloy, a set of optimal parameters was successfully inverted, and the agreement between simulation results and experimental data validated the method's effectiveness. This study provides valuable insights for predicting the mechanical behaviors, guiding material design, and optimizing the performances of refractory high-entropy alloys.

-

表 1 试验设计各因素的取值范围

Table 1. The range of values for each factor in the experimental design

design variable symbol lower limit upper limit initial hardening modulus h0/MPa 100 500 saturation stress τs/MPa 220 780 initial critical resolved shear stress τ0/MPa 200 700 rate sensitivity exponent n0 30 80 reference slip shear rate $\dot{\gamma}$0/s-1 2×10-3 5×10-3 Peierls stress τp0/MPa 300 900 reference strain rate $\dot{\gamma}$p0/s-1 5.7×107 1.51×108 kink-pair formation enthalpy Hk/eV 0.38 0.56 表 2 参数单因素分析的设计变量取值情况

Table 2. Design variable values for parametric univariate analysis of variance

design variable symbol level 1 level 2 level 3 level 4 level 5 rate sensitivity exponent n0 30 15 22.5 37.5 45 initial critical resolved shear stress τ0/MPa 300 150 225 375 450 Peierls stress τp0/MPa 500 250 375 625 750 kink-pair formation enthalpy Hk/eV 0.62 0.31 0.47 0.78 0.94 saturation stress τs/MPa 600 - - - - initial hardening modulus h0/MPa 200 - - - - reference slip shear rate $\dot{\gamma}$0/s-1 3×10-3 - - - - reference strain rate $\dot{\gamma}$p0/s-1 1×108 - - - - 表 3 铸态TiZrNbV高熵合金的晶体塑性本构模型参数

Table 3. Crystal plasticity constitutive model parameters for cast TiZrNbV high-entropy alloys

design variable symbol value initial hardening modulus h0/MPa 91 saturation stress τs/MPa 430 initial critical resolved shear stress τ0/MPa 410 rate sensitivity exponent n0 34 reference slip shear rate $\dot{\gamma}$0/s-1 3.6×10-3 Peierls stress τp0/MPa 320 reference strain rate $\dot{\gamma}$p0/s-1 9.2×107 kink-pair formation enthalpy Hk/eV 0.60 -

[1] SENKOV O N, SENKOVA S V, MIRACLE D B, et al. Mechanical properties of low-density, refractory multi-principal element alloys of the Cr-Nb-Ti-V-Zr system[J]. Materials Science and Engineering: A, 2013, 565: 51-62. doi: 10.1016/j.msea.2012.12.018 [2] MIRACLE D B, SENKOV O N. A critical review of high entropy alloys and related concepts[J]. Acta Materialia, 2017, 122: 448-511. doi: 10.1016/j.actamat.2016.08.081 [3] SENKOV O N, RAO S, CHAPUT K J, et al. Compositional effect on microstructure and properties of NbTiZr-based complex concentrated alloys[J]. Acta Materialia, 2018, 151: 201-215. doi: 10.1016/j.actamat.2018.03.065 [4] 唐宇, 王睿鑫, 李顺, 等. 高熵合金含能结构材料的潜力与挑战[J]. 含能材料, 2021, 29(10): 1008-1018. doi: 10.11943/CJEM2021087TANG Yu, WANG Ruixin, LI Shun, et al. Potential and challenges of high-entropy alloy energetic structural materials[J]. Chinese Journal of Energetic Materials, 2021, 29(10): 1008-1018. (in Chinese) doi: 10.11943/CJEM2021087 [5] 梁秀兵, 万义兴, 莫金勇, 等. 新型高温高熵合金材料研究进展[J]. 科技导报, 2021, 39(11): 96-108.LIANG Xiubing, WAN Yixing, MO Jinyong, et al. Research progress in novel high-temperature high entropy alloys[J]. Science & Technology Review, 2021, 39(11): 96-108. (in Chinese) [6] SENKOV O N, WOODWARD C F. Microstructure and properties of a refractory NbCrMo0.5Ta0.5TiZr alloy[J]. Materials Science and Engineering: A, 2011, 529: 311-320. doi: 10.1016/j.msea.2011.09.033 [7] MENG J, SHEN B, WANG J, et al. Energy-release behavior of TiZrNbV high-entropy alloy[J]. Intermetallics, 2023, 162: 108036. doi: 10.1016/j.intermet.2023.108036 [8] MENG J Y, HE J Z, ZHANG B, et al. The effect of Ti and Zr content on the structure, mechanics and energy-release characteristics of Ti-Zr-Ta alloys[J]. Defence Technology, 2024, 31: 343-350. doi: 10.1016/j.dt.2023.01.007 [9] XIE Q, ZHU Z, KANG G, et al. Crystal plasticity-based impact dynamic constitutive model of magnesium alloy[J]. International Journal of Mechanical Sciences, 2016, 119: 107-113. doi: 10.1016/j.ijmecsci.2016.10.012 [10] LU Y, ZHU Z, LI D, et al. Constitutive model of 42CrMo steel under a wide range of strain rates based on crystal plasticity theory[J]. Materials Science and Engineering: A, 2017, 679: 215-222. doi: 10.1016/j.msea.2016.09.117 [11] BOBBILI R, MADHU V. Constitutive modeling of dynamic flow behavior of Ti-5553 alloy[J]. Journal of Alloys and Compounds, 2019, 787: 260-266. doi: 10.1016/j.jallcom.2019.02.101 [12] RAABE D, SACHTLEBER M, ZHAO Z, et al. Micromechanical and macromechanical effects in grain scale polycrystal plasticity experimentation and simulation[J]. Acta Materialia, 2001, 49(17): 3433-3441. doi: 10.1016/S1359-6454(01)00242-7 [13] BERTIN M, DU C, HOEFNAGELS J P M, et al. Crystal plasticity parameter identification with 3D measurements and integrated digital image correlation[J]. Acta Materialia, 2016, 116: 321-331. doi: 10.1016/j.actamat.2016.06.039 [14] GALLARDO-BASILE F J, ROTERS F, JENTNER R M, et al. Application of a nanoindentation-based approach for parameter identification to a crystal plasticity model for bcc metals[J]. Materials Science and Engineering: A, 2023, 881: 145373. doi: 10.1016/j.msea.2023.145373 [15] CHAKRABORTY A, EISENLOHR P. Evaluation of an inverse methodology for estimating constitutive parameters in face-centered cubic materials from single crystal indentations[J]. European Journal of Mechanics-A/Solids, 2017, 66: 114-124. doi: 10.1016/j.euromechsol.2017.06.012 [16] HERRERA-SOLAZ V, LLORCA J, DOGAN E, et al. An inverse optimization strategy to determine single crystal mechanical behavior from polycrystal tests: application to AZ31 Mg alloy[J]. International Journal of Plasticity, 2014, 57: 1-15. doi: 10.1016/j.ijplas.2014.02.001 [17] JI H S, SONG Q H, GUPTA M K, et al. Grain scale modelling and parameter calibration methods in crystal plasticity finite element researches: a short review[J]. Journal of Advanced Manufacturing Science and Technology, 2021, 1(2): 2021005. doi: 10.51393/j.jamst.2021005 [18] SEDIGHIANI K, DIEHL M, TRAKA K, et al. An efficient and robust approach to determine material parameters of crystal plasticity constitutive laws from macro-scale stress-strain curves[J]. International Journal of Plasticity, 2020, 134: 102779. doi: 10.1016/j.ijplas.2020.102779 [19] SUN X C, WANG H M. A method for crystal plasticity model parameter calibration based on Bayesian optimization[M]//Magnesium Technology 2022. Cham: Springer International Publishing, 2022: 105-111. [20] 周瑞, 熊宇凯, 储节磊, 等. 基于机器学习和遗传算法的非局部晶体塑性模型参数识别[J]. 力学学报, 2024, 56(3): 751-762.ZHOU Rui, XIONG Yukai, CHU Jielei, et al. Parameter identification of nonlocal crystal plastic model based on machine learning and genetic algorithm[J]. Chinese Journal of Theoretical and Applied Mechanics, 2024, 56(3): 751-762. (in Chinese) [21] XU S, AN X, QIAO X, et al. Multi-output least-squares support vector regression machines[J]. Pattern Recognition Letters, 2013, 34(9): 1078-1084. doi: 10.1016/j.patrec.2013.01.015 [22] 王兰, 董宜平, 曹进德. 基于准ARX模型和SVR算法的非线性系统切换控制[J]. 应用数学和力学, 2022, 43(11): 1281-1287. doi: 10.21656/1000-0887.430122WANG Lan, DONG Yiping, CAO Jinde. Switching control of nonlinear systems based on the quasi-ARX model and the SVR algorithm[J]. Applied Mathematics and Mechanics, 2022, 43(11): 1281-1287. (in Chinese) doi: 10.21656/1000-0887.430122 [23] 章海明, 徐帅, 李倩, 等. 晶体塑性理论及模拟研究进展[J]. 塑性工程学报, 2020, 27(5): 12-32.ZHANG Haiming, XU Shuai, LI Qian, et al. Progress of crystal plasticity theory and simulations[J]. Journal of Plasticity Engineering, 2020, 27(5): 12-32. (in Chinese) [24] HILL R, RICE J R. Constitutive analysis of elastic-plastic crystals at arbitrary strain[J]. Journal of the Mechanics and Physics of Solids, 1972, 20(6): 401-413. doi: 10.1016/0022-5096(72)90017-8 [25] REN K, LIU H, CHEN R, et al. Compression properties and impact energy release characteristics of TiZrNbV high-entropy alloy[J]. Materials Science and Engineering: A, 2021, 827: 142074. doi: 10.1016/j.msea.2021.142074 [26] WANG J, BAI S, TANG Y, et al. Effect of the valence electron concentration on the yield strength of Ti-Zr-Nb-V high-entropy alloys[J]. Journal of Alloys and Compounds, 2021, 868: 159190. doi: 10.1016/j.jallcom.2021.159190 [27] WEINBERGER C R, BOYCE B L, BATTAILE C C. Slip planes in BCC transition metals[J]. International Materials Reviews, 2013, 58(5): 296-314. doi: 10.1179/1743280412Y.0000000015 [28] CARROLL J D, CLARK B G, BUCHHEIT T E, et al. An experimental statistical analysis of stress projection factors in BCC tantalum[J]. Materials Science and Engineering: A, 2013, 581: 108-118. doi: 10.1016/j.msea.2013.05.085 [29] HUTCHINSON J W. Bounds and self-consistent estimates for creep of polycrystalline materials[J]. Proceedings of the Royal Society A: Mathematical and Physical Sciences, 1976, 348(1652): 101-127. [30] TERENTYEV D, XIAO X, DUBINKO A, et al. Dislocation-mediated strain hardening in tungsten: thermo-mechanical plasticity theory and experimental validation[J]. Journal of the Mechanics and Physics of Solids, 2015, 85: 1-15. [31] LIM H, BATTAILE C C, CARROLL J D, et al. A physically based model of temperature and strain rate dependent yield in BCC metals: implementation into crystal plasticity[J]. Journal of the Mechanics and Physics of Solids, 2015, 74: 80-96. doi: 10.1016/j.jmps.2014.10.003 [32] PEIRCE D, ASARO R J, NEEDLEMAN A. An analysis of nonuniform and localized deformation in ductile single crystals[J]. Acta Metallurgica, 1982, 30(6): 1087-1119. doi: 10.1016/0001-6160(82)90005-0 [33] WU Y C, YAN Y F, LV Z M. Novel prediction model for steel mechanical properties with MSVR based on MIC and complex network clustering[J]. Metals, 2021, 11(5): 747. doi: 10.3390/met11050747 [34] KATOCH S, CHAUHAN S S, KUMAR V. A review on genetic algorithm: past, present, and future[J]. Multimedia Tools and Applications, 2021, 80(5): 8091-8126. doi: 10.1007/s11042-020-10139-6 [35] BIGGS M B. Sequential quadratic programming[M]//Nonlinear Optimization With Engineering Applications. Boston, MA: Springer US, 2008: 1-14. [36] QUEY R, RENVERSADE L. Optimal polyhedral description of 3D polycrystals: method and application to statistical and synchrotron X-ray diffraction data[J]. Computer Methods in Applied Mechanics and Engineering, 2018, 330: 308-333. doi: 10.1016/j.cma.2017.10.029 [37] SPETTL A, WERZ T, KRILL C E, et al. Parametric representation of 3D grain ensembles in polycrystalline microstructures[J]. Journal of Statistical Physics, 2014, 154(4): 913-928. doi: 10.1007/s10955-013-0893-7 [38] 王姝予, 宋世杰, 陆晓翀, 等. CrMnFeCoNi高熵合金拉伸断裂的晶体塑性有限元模拟[J]. 机械工程学报, 2021, 57(22): 43-51.WANG Shuyu, SONG Shijie, LU Xiaochong, et al. Tensile fracture behavior of the CrMnFeCoNi high entropy alloy: a crystal plasticity finite element simulation[J]. Journal of Mechanical Engineering, 2021, 57(22): 43-51. (in Chinese) [39] HU P, LIU Y, ZHU Y, et al. Crystal plasticity extended models based on thermal mechanism and damage functions: application to multiscale modeling of aluminum alloy tensile behavior[J]. International Journal of Plasticity, 2016, 86: 1-25. doi: 10.1016/j.ijplas.2016.07.001 [40] TIAN L Y, WANG G, HARRIS J S, et al. Alloying effect on the elastic properties of refractory high-entropy alloys[J]. Materials & Design, 2017, 114: 243-252. [41] 范婉婉, 王涛, 侯洁, 等. 基于CPRVE模型的304不锈钢极薄箔材参数标定[J]. 塑性工程学报, 2019, 26(4): 268-273.FAN Wanwan, WANG Tao, HOU Jie, et al. Parameters calibration of 304 stainless steel ultra-thin foil based on CPRVE model[J]. Journal of Plasticity Engineering, 2019, 26(4): 268-273. (in Chinese) [42] 惠文. 基于CPFEM的TA15钛合金高温塑性变形研究[D]. 合肥: 合肥工业大学, 2013.HUI Wen. Rsesearch on the plastic deformation of TA15 titanium alloy at high temperature using CPFEM[D]. Hefei: Hefei University of Technology, 2013. (in Chinese) [43] XUE J K, SHEN B. A novel swarm intelligence optimization approach: sparrow search algorithm[J]. Systems Science & Control Engineering, 2020, 8(1): 22-34. -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号