The Calculation Method and Application of Fluid-Solid Coupling Vibration Responses of Straight Infusion Pipeline

-

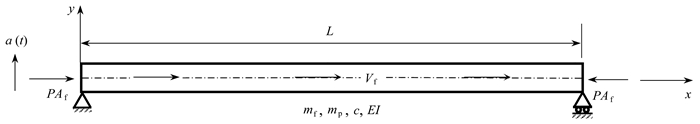

摘要: 输液管道系统中存在液体压力脉动和管道结构的高度非线性耦合效应,在外激励作用下将产生剧烈的耦合振动现象,严重时会导致输液管道及连接结构失效.针对输液管道流-固耦合振动响应解析方法缺乏,研究了基于微分变换法(DTM)求解含复杂支承的输液管道系统动力学特性及振动响应理论,基于Bernoulli-Euler梁理论建立了跨中含复杂弹性支承的输液直管道流-固耦合振动微分方程,详细推导了基于DTM计算简支、含附加弹性支承输液直管道系统固有频率、位移响应及支承约束反力的表达式,研究了输液管道内压强、流速及附加支承刚度和位置对管道系统固有频率、支承约束反力的影响,并基于结构有限元分析方法验证了DTM的计算精度.研究表明:采用DTM计算含复杂支承输液管道系统流-固耦合振动特性及响应的精度高、适用性强,尤其在复杂边界以及跨中含有附加支承管道系统振动响应计算方面具有明显的优势,基于DTM可以便捷计算流固耦合管道系统强迫振动中的力学响应,为管道及其连接结构的设计提供理论依据.Abstract: There is a highly nonlinear coupling effect between liquid pressure pulsation and pipeline structure in the infusion pipeline system. Severe coupling vibration will occur under external excitation, which will lead to the failure of the infusion pipeline and connection structure. In view of the lack of analytical methods for the fluid-solid coupling vibration responses of the infusion pipeline, the dynamic characteristics and vibration response theory for the infusion pipeline system with complex supports were given based on the differential transformation method (DTM), and the fluid-solid coupling vibration differential equation for the straight infusion pipeline with complex elastic supports within the span was established based on the Bernoulli-Euler beam theory. The expressions based on the DTM for calculating natural frequencies, displacement responses and support constraint reactions of the pipeline system with the simple support and additional elastic supports were derived in detail. The influences of the internal pressure, the flow rate, the additional support stiffness and the support position on natural frequencies and support constraint reactions of the pipeline system were studied, and the calculation accuracy of the DTM was verified with the structural finite element analysis method. The research shows that, the application of the DTM in the calculation of fluid-solid coupling vibration characteristics and responses of the infusion pipeline system with complex supports has high accuracy and good applicability, especially in the calculation of vibration responses of the pipeline system with complex boundaries and additional supports within the span. Based on the DTM, the mechanical responses of the fluid-solid coupling pipeline system can be conveniently calculated under forced vibration. It provides a theoretical basis for the design of pipelines and connected structures.

-

original function conversion function w(x)=y(x)±z(x) W(k)=Y(k)±Z(k) w(x)=Ay(x) W(k)=AY(k) $w(x)=\frac{\mathrm{d} y(x)}{\mathrm{d} x} $ W(k)=(k+1)Y(k+1) $w(x)=\frac{\mathrm{d}^{n} y(x)}{\mathrm{d} x^{n}} $ W(k)=(k+1)(k+2)…(k+n)Y(k+n) w(x)=y(x)z(x) $ W(k)=\sum\limits_{l=0}^{k} Y(l) Z(k-l)$ w(x)=xm $ W(k)=\delta(k-m)= \begin{cases}1, & k=m \\ 0, & k \neq m\end{cases}$ boundary type boundary condition conversion condition η(0)=η″(0)=0

η(1)=η″(1)=0W(0)=W(2)=0

$\sum\limits_{k=0}^{N} W(k)=\sum\limits_{k=0}^{N} k(k-1) W(k)=0 $η(0)=η′(0)=0

η″(1)=η'''(1)=0W(0)=W(1)=0

$ \sum\limits_{k=0}^{N} k(k-1) W(k)=\sum\limits_{k=0}^{N} k(k-1)(k-2) W(k)=0$η(0)=η′(0)=0

η(1)=η″(1)==0W(0)=W(1)=0

$\sum\limits_{k=0}^{N} W(k)=\sum\limits_{k=0}^{N} k(k-1) W(k)=0 $η(0)=η′(0)=0

η(1)=η′(1)=0W(0)=W(1)=0

$ \sum\limits_{k=0}^{N} W(k)=\sum\limits_{k=0}^{N} k W(k)=0$表 3 简支输液管道系统固有频率计算结果

Table 3. Calculation results of natural frequencies of the simple support infusion pipeline system

flow condition natural frequency fi/Hz error δ/% P/MPa Vf/(m/s) i FEM DTM 0 0 1 86.772 86.772 0 2 347.134 346.549 0.17 20 10 1 69.0 69.0 0 2 330.768 330.189 0.18 30 20 1 57.80 57.80 0 2 322.1 321.491 0.19 表 4 输液管道系统简支端约束反力

Table 4. Constraining reactions at the simple support end of the infusion pipeline system

excitation frequency ωf flow condition constrained reaction force R1/N error δ/% P/MPa Vf/(m/s) FEM DTM 0.5ω1 0 0 17.018 17.166 0.87 20 10 30.914 31.109 0.63 30 20 58.257 58.852 1 ω1 0 0 2 526.348 2 527.190 0.03 20 10 27.528 27.692 0.6 30 20 17.129 17.343 0.5 1.5ω1 0 0 6.339 6.242 1.5 20 10 4.497 4.187 6.7 30 20 3.808 3.518 7.6 表 5 等支承约束反力设计

Table 5. The equal support constrained reaction force design

flow condition ωf optimal addition stiffness k/(kN/m) f1/Hz constrained reaction force Rj/N error δ/% P/MPa Vf/(m/s) j DTM FEM 20 10 1 12.407 12.112 2.38 0.5ω1 416.0 110.942 k 12.40 12.435 0.28 2 12.407 12.112 2.38 1 30.569 30.410 0.52 ω1 347.1 105.260 k 30.540 30.813 0.89 2 30.569 30.410 0.52 1 9.224 9.396 1.86 1.5ω1 231.8 94.920 k 9.215 9.181 0.37 2 9.224 9.396 1.86 30 20 1 14.293 14.0 2.05 0.5ω1 402.3 103.137 k 14.279 14.330 0.36 2 14.293 14.0 2.05 1 55.774 55.925 0.27 ω1 332.6 96.927 k 55.722 56.521 1.43 2 55.774 55.925 0.27 1 7.144 7.276 1.84 1.5ω1 217.5 85.606 k 7.138 7.126 0.17 2 7.144 7.276 1.84 -

[1] LIANG Feng, QIAN Yu, CHEN Yao, et al. Nonlinear forced vibration of spinning pipes conveying fluid under lateral harmonic excitation[J]. International Journal of Applied Mechanics, 2021, 13(9): 2150098. doi: 10.1142/S1758825121500988 [2] 张凯凯, 谭霞, 丁虎, 等. 超临界输流管道3∶1内共振下参激振动响应[J]. 应用数学和力学, 2018, 39(11): 1227-1235. doi: 10.21656/1000-0887.390121ZHANG Kaikai, TAN Xia, DING Hu, et al. Parametric vibration responses of supercritical fluid-conveying pipes in 3∶1 internal resonance[J]. Applied Mathematics and Mechanics, 2018, 39(11): 1227-1235. (in Chinese) doi: 10.21656/1000-0887.390121 [3] LI Qian, LIU Wei, LU Kuan, et al. Nonlinear parametric vibration of a fluid-conveying pipe flexibly restrained at the ends[J]. Acta Mechanica Solida Sinica, 2020, 33(3): 327-346. doi: 10.1007/s10338-019-00147-x [4] GAO Xumin, GAO Peixin, MA Hui, et al. Vibration characteristics analysis of fluid-conveying pipes concurrently subjected to base excitation and pulsation excitation[J]. Mechanical Systems and Signal Processing, 2023, 189: 110086. doi: 10.1016/j.ymssp.2022.110086 [5] 唐冶, 方勃, 张业伟, 等. 非线性弹簧支承悬臂输液管道的分岔与混沌分析[J]. 振动与冲击, 2011, 30(8): 269-274.TANG Ye, FANG Bo, ZHANG Yewei, et al. Bifurcation and chaos analysis of cantilever pipeline conveying fluid with nonlinear spring support[J]. Journal of Vibration and Shock, 2011, 30(8): 269-274. (in Chinese) [6] 包日东, 闻邦椿. 微分求积法分析弹性支承输流管道的稳定性[J]. 东北大学学报(自然科学版), 2007, 28(7): 1017-1020.BAO Ridong, WEN Bangchun. Differential quadrature method to analyze stability of elastically-supported fluid conveying pipelines[J]. Journal of Northeastern University (Natural Science), 2007, 28(7): 1017-1020. (in Chinese) [7] 毛晓晔, 丁虎, 陈立群. 3∶1内共振下超临界输液管受迫振动响应[J]. 应用数学和力学, 2016, 37(4): 345-351. doi: 10.3879/j.issn.1000-0887.2016.04.002MAO Xiaoye, DING Hu, CHEN Liqun. Forced vibration responses of supercritical fluid-conveying pipes in 3∶1 internal resonance[J]. Applied Mathematics and Mechanics, 2016, 37(4): 345-351. (in Chinese) doi: 10.3879/j.issn.1000-0887.2016.04.002 [8] LI S J, LIU G M, KONG W T. Vibration analysis of pipes conveying fluid by transfer matrix method[J]. Nuclear Engineering and Design, 2014, 266: 78-88. doi: 10.1016/j.nucengdes.2013.10.028 [9] 赵千里. 输流管路流固耦合振动特性研究及共振可靠性分析[D]. 沈阳: 东北大学, 2019.ZHAO Qianli. Analysis for fluid structure interaction vibration characteristics and resonance reliability of fluid conveying pipe[D]. Shenyang: Northeastern University, 2019. (in Chinese) [10] SAZESH S, SHAMS S. Vibration analysis of cantilever pipe conveying fluid under distributed random excitation[J]. Journal of Fluids and Structures, 2019, 87: 84-101. doi: 10.1016/j.jfluidstructs.2019.03.018 [11] 袁嘉瑞, 丁虎, 陈立群. 微曲输流管道振动固有频率分析与仿真[J]. 应用数学和力学, 2022, 43(7): 719-726. doi: 10.21656/1000-0887.420299YUAN Jiarui, DING Hu, CHEN Liqun. Analysis and simulation of natural frequencies of slightly curved pipes[J]. Applied Mathematics and Mechanics, 2022, 43(7): 719-726. (in Chinese) doi: 10.21656/1000-0887.420299 [12] 孙诣博, 魏莎, 丁虎, 等. 基于路径积分法的输液管道随机动态响应分析[J]. 力学学报, 2023, 55(6): 1371-1381.SUN Yibo, WEI Sha, DING Hu, et al. Stochastic dynamic response analysis of pipe conveying fluid based on the path integral method[J]. Chinese Journal of Theoretical and Applied Mechanics, 2023, 55(6): 1371-1381. (in Chinese) [13] 颜雄, 魏莎, 毛晓晔, 等. 两端弹性支承输流管道固有特性研究[J]. 力学学报, 2022, 54(5): 1341-1352.YAN Xiong, WEI Sha, MAO Xiaoye, et al. Study on natural characteristics of fluid-conveying pipes with elastic supports at both ends[J]. Chinese Journal of Theoretical and Applied Mechanics, 2022, 54(5): 1341-1352. (in Chinese) [14] 熊宇, 张怀亮, 彭欢. 一种新型液压管道抗振支承研究[J]. 噪声与振动控制, 2017, 37(2): 168-172.XIONG Yu, ZHANG Huailiang, PENG Huan. Research on a new type of anti-vibration supports for hydraulic pipelines[J]. Noise and Vibration Control, 2017, 37(2): 168-172. (in Chinese) [15] 王晶, 陈果, 郑其辉, 等. 卡箍对飞机液压管道动态应力的影响分析[J]. 航空计算技术, 2014, 44(1): 64-67.WANG Jing, CHEN Guo, ZHENG Qihui, et al. Effect of clamp on aircraft hydraulic pipeline dynamic stress[J]. Aeronautical Computing Technique, 2014, 44(1): 64-67. (in Chinese) [16] 李枫, 刘伟, 韦顺超, 等. 航空液压管道卡箍等效刚度及其影响因素研究[J]. 机械科学与技术, 2017, 36(9): 1472-1476.LI Feng, LIU Wei, WEI Shunchao, et al. Research on equivalent stiffness and influence factors of aero-clamps for aircraft hydraulic pipelines[J]. Mechanical Science and Technology for Aerospace Engineering, 2017, 36(9): 1472-1476. (in Chinese) [17] 赵家奎. 微分变换及其在电路中的应用[M]. 武汉: 华中理工大学出版社, 1986.ZHAO Jiakui. Differential Transformation and Its Application in Circuits[M]. Wuhan: Huazhong University of Science and Technology Press, 1986. (in Chinese) [18] 林彬, 李开泰. 求解非线性微分方程的微分变换方法[J]. 兰州大学学报(自然科学版), 2009, 45(6): 132-135.LIN Bin, LI Kaitai. Differential transformation method for solving nonlinear differential equations[J]. Journal of Lanzhou University (Natural Sciences), 2009, 45(6): 132-135. (in Chinese) [19] TIAN R, WANG D. Optimal design of beam structure support for controlling reaction force during vibration[C]//The 26th International Congress on Sound and Vibration. Montréal, 2019. [20] 田瑞, 王栋. 梁结构振动支承约束反力控制[J]. 噪声与振动控制, 2021, 41(2): 50-55.TIAN Rui, WANG Dong. Optimal design of beam structure supports for controlling constraint reaction forces during vibration[J]. Noise and Vibration Control, 2021, 41(2): 50-55. (in Chinese) [21] 任建亭, 姜节胜. 输流管道系统振动研究进展[J]. 力学进展, 2003, 33(3): 313-324.REN Jianting, JIANG Jiesheng. Advances and trends on vibration of pipes conveying fluid[J]. Advances in Mechanics, 2003, 33(3): 313-324. (in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号