Simulation Study of Porosity Effects of Porous Media on Pool Boiling Heat Transfer Performances

-

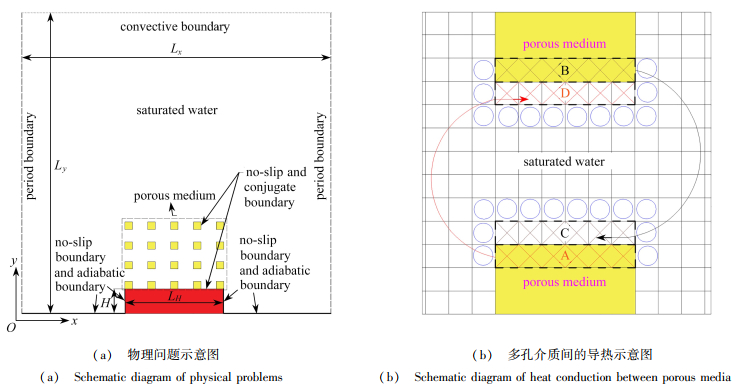

摘要: 采用介观相变格子Boltzmann(lattice Boltzmann, LB)方法,在孔隙尺度下研究了多孔介质的孔隙率对池沸腾换热过程的影响,重点分析了不同孔隙率时气泡的运动过程,并对气泡在多孔介质中的典型状态进行了力平衡分析,进而探究了多孔介质孔隙率影响沸腾传热的机理.结果表明,与无多孔介质的平板表面相比,多孔材料能够有效地降低初始成核的壁面过热度,增强流体的扰动,并且能够显著提升临界热流密度(critical heat flux,CHF)值.在所研究的工况中,孔隙率ε=73.2%时,CHF值提升最大,约为平板的3.6倍,其余孔隙率的多孔介质最小也可将其CHF值提升至平板的2.3倍.研究发现,当孔隙率从97.7%开始逐渐减小时,CHF值逐渐增大,同时沸腾换热曲线向左上方移动,这是因为减小孔隙率能够增大有效换热面积,减小气泡成核的壁面过热度,从而强化沸腾换热.当孔隙率减小到ε=73.2%时,若继续减小孔隙率,热流密度将突然下降,沸腾传热性能显著降低.通过对沸腾过程中气泡的受力进行分析后发现,当孔隙率较小时,过小的孔隙直径显著增大了气泡的逸出阻力,降低了气泡的上升速度,延长了气泡脱离多孔介质的时间,且此时气泡会在蒸发动量力、接触压力以及摩擦力等的共同作用下聚集在加热器上表面,形成气膜,从而恶化沸腾传热.Abstract: The mesoscopic phase change lattice Boltzmann method was used to study the effect of the medium porosity on pool boiling heat transfer at the pore scale. The motion processes of bubbles were mainly considered for different porosities, and the force balance was analyzed in typical states of bubbles in porous media, to explore the mechanism of the influence of medium porosity on boiling heat transfer. The results show that, compared with the flat surface without a porous medium, porous materials can effectively reduce the wall superheat of initial nucleation, enhance the disturbance of fluid, and significantly improve the critical heat flux (CHF). In the simulation case, the CHF value grows the greatest with porosity ε=73.2%, which is about 3.6 times that of the flat plate case. In the cases of other porosity values, the presence of porous media can increase the CHF value for at least 2.3 times that of the flat plate case. The numerical simulation further demonstrates that, as the porosity gradually decreases from 97.7%, the CHF value will gradually increases, and the boiling heat transfer curve will shift to the upper left. This is because a decrease in the porosity can increase the effective heat transfer area, reduce the wall superheat of bubble nucleation, and strengthen boiling heat transfer. When the porosity decreases to ε=73.2%, the heat flux density will suddenly drop and the boiling heat transfer performance will significantly decrease with the reduction of the porosity. The analysis of force balance of the bubbles during the boiling process indicates that, for a low porosity, too small pore diameters would significantly increase the escape resistance of bubbles, reduce their rising speed, and lengthen the time of bubbles leaving the porous medium; at the same time, bubbles will gather on the surface of the heater under the combined actions of the evaporation momentum, the contact pressure, and the friction, thus deteriorating the boiling heat transfer performance.

-

Key words:

- porous medium /

- pool boiling heat transfer /

- bubble dynamics /

- porosity

-

表 1 格子单位与物理单位转换

Table 1. The unit conversion from lattice units to physical units

parameter lattice unit physical unit conversion factor ρl 5.426 570.02 kg/m3 106.16 kg/m3 ρv 0.811 3 86.13 kg/m3 106.16 kg/m3 l0 16 4.72×10-6 m 2.95×10-7 m u0 0.035 8 38.56 m/s 1 077.09 m/s t0 447.8 1.224×10-7 s 2.734×10-10 s ν 0.06 1.9×10-5 m2/s 3.18×10-4 m2/s Tc 0.196 1 647.2 K 3 300.36 K pc 0.178 4 2.21×107 Pa 1.24×108 Pa cv, l 4.0 1 405.9 J/(kg· K) 351.48 J/(kg· K) hfg 0.624 7.26×105 J/kg 1.16×106 J/kg λs 32.556 390.67 W/(m· K) 12 W/(m· K) 表 2 不同孔隙率的多孔介质样本其气泡最大接触压力Fcpm以及平均上升速度Vave(格子单位)

Table 2. Maximum contact pressures of bubbles in porous medium samples with different porosities Fcpm and average rising speeds Vave (lattice units)

porosity ε/% t* Rr da σ Fcpm Vave 97.7 33.50 47.37 258.79 0.009 5 10.55 4.50×10-6 92.6 37.96 51.06 285.21 0.009 5 11.89 5.24×10-6 85.2 42.43 51.53 289.66 0.009 5 12.15 4.38×10-6 73.2 46.90 50.20 312.58 0.009 5 14.52 4.30×10-6 67.6 53.60 56.84 353.96 0.009 5 16.45 3.83×10-6 61.2 58.06 58.80 372.42 0.009 5 17.60 3.49×10-6 53.5 69.23 56.44 374.01 0.009 5 18.49 2.60×10-6 -

[1] DEDOV A V, KHAZIEV I A, LAHAREV D A, et al. Study of nucleate pool boiling heat transfer enhancement on surfaces modified by beam technologies[J]. Heat Transfer Engineering, 2022, 43(7): 598-607. doi: 10.1080/01457632.2021.1896834 [2] 李迎雪, 王浩原, 娄钦. 含多个矩形加热器通道内流动沸腾传热性能的介观数值方法研究[J]. 应用数学和力学, 2022, 43(7): 727-739. doi: 10.21656/1000-0887.420325LI Yingxue, WANG Haoyuan, LOU Qin. Mesoscopic numerical study on flow boiling heat transfer performance in channels with multiple rectangular heaters[J]. Applied Mathematics and Mechanics, 2022, 43(7): 727-739. (in Chinese) doi: 10.21656/1000-0887.420325 [3] YANG Z, YAO Y, WU H. Effects of surfactants on subcooled pool boiling characteristics: an experimental study[J]. International Journal of Heat and Mass Transfer, 2022, 199: 123419. doi: 10.1016/j.ijheatmasstransfer.2022.123419 [4] ZONOUZI S A, AMINFAR H, MOHAMMADPOURFARD M. A review on effects of magnetic fields and electric fields on boiling heat transfer and CHF[J]. Applied Thermal Engineering, 2019, 151: 11-25. doi: 10.1016/j.applthermaleng.2019.01.099 [5] ALIZADEH R, GOMARI S R, ALIZADEH A, et al. Combined heat and mass transfer and thermodynamic irreversibilities in the stagnation-point flow of Casson rheological fluid over a cylinder with catalytic reactions and inside a porous medium under local thermal nonequilibrium[J]. Computers and Mathematics With Applications, 2021, 81: 786-810. doi: 10.1016/j.camwa.2019.10.021 [6] DEHGHAN M, VALIPOUR M S, KESHMIRI A, et al. On the thermally developing forced convection through a porous material under the local thermal non-equilibrium condition: an analytical study[J]. International Journal of Heat and Mass Transfer, 2016, 92: 815-823. doi: 10.1016/j.ijheatmasstransfer.2015.08.091 [7] EL-GENK M S, PARKER J L. Enhanced boiling of HFE-7100 dielectric liquid on porous graphite[J]. Energy Conversion and Management, 2005, 46(15/16): 2455-2481. [8] CHI Y L, BHUIYA M, KIM K J. Pool boiling heat transfer with nano-porous surface[J]. International Journal of Heat and Mass Transfer, 2010, 53(19/20): 4274-4279. [9] BERGLES A E, CHYU M C. Characteristics of nucleate pool boiling from porous metallic coatings[J]. ASME Journal of Heat and Mass Transfer, 1982, 104(2): 279-285. doi: 10.1115/1.3245084 [10] YANG Y, JI X, XU J. Pool boiling heat transfer on copper foam covers with water as working fluid[J]. International Journal of Thermal Sciences, 2010, 49(7): 1227-1237. doi: 10.1016/j.ijthermalsci.2010.01.013 [11] LI C, WANG Z, WANG P I, et al. Nanostructured copper interfaces for enhanced boiling[J]. Small, 2008, 4(8): 1084-1088. doi: 10.1002/smll.200700991 [12] ZHANG B J, KIM K J, YOON H. Enhanced heat transfer performance of alumina sponge-like nano-porous structures through surface wettability control in nucleate pool boiling[J]. International Journal of Heat and Mass Transfer, 2012, 55(25/26): 7487-7498. [13] ZHANG B J, PARK J, KIM K J. Augmented boiling heat transfer on the wetting-modified three dimensionally-interconnected alumina nano porous surfaces in aqueous polymeric surfactants[J]. International Journal of Heat and Mass Transfer, 2013, 63: 224-232. doi: 10.1016/j.ijheatmasstransfer.2013.03.064 [14] MORI S, OKUYAMA K. Enhancement of the critical heat flux in saturated pool boiling using honeycomb porous media[J]. International Journal of Multiphase Flow, 2009, 35(10): 946-951. doi: 10.1016/j.ijmultiphaseflow.2009.05.003 [15] YUKI K, HARA T, IKEZAWA S, et al. Immersion cooling of electronics utilizing lotus-type porous copper[J]. Transactions of the Japan Institute of Electronics Packaging, 2016, 9: E16-013. [16] JI X, XU J, ZHAO Z, et al. Pool boiling heat transfer on uniform and non-uniform porous coating surfaces[J]. Experimental Thermal and Fluid Science, 2013, 48: 198-212. doi: 10.1016/j.expthermflusci.2013.03.002 [17] AN Y, HUANG C, WANG X. Effects of thermal conductivity and wettability of porous materials on the boiling heat transfer[J]. International Journal of Thermal Sciences, 2021, 170: 107-110. [18] LI H Y, LEONG K C. Experimental and numerical study of single and two-phase flow and heat transfer in aluminum foams[J]. International Journal of Heat and Mass Transfer, 2011, 54(23/24): 4904-4912. [19] PERALTA M, MENDEZ F, BAUTISTA O. Phase-change transpiration cooling in a porous medium: determination of the liquid/two-phase/vapor interfaces as a problem of eigenvalues[J]. Transport in Porous Media, 2016, 112(1): 167-187. doi: 10.1007/s11242-016-0637-7 [20] SHAN X, CHEN H. Lattice Boltzmann model for simulating flows with multiple phases and components[J]. Physical Review E, 1993, 47(3): 1815-1819. doi: 10.1103/PhysRevE.47.1815 [21] CHEN L, KANG Q, MU Y, et al. A critical review of the pseudopotential multiphase lattice Boltzmann model: methods and applications[J]. International Journal of Heat and Mass Transfer, 2014, 76: 210-236. doi: 10.1016/j.ijheatmasstransfer.2014.04.032 [22] GONG S, CHENG P. Lattice Boltzmann simulation of periodic bubble nucleation, growth and departure from a heated surface in pool boiling[J]. International Journal of Heat and Mass Transfer, 2013, 64: 122-132. doi: 10.1016/j.ijheatmasstransfer.2013.03.058 [23] LI Q, ZHOU P, YAN H J. Improved thermal lattice Boltzmann model for simulation of liquid-vapor phase change[J]. Physical Review E, 2017, 96(6): 063303. doi: 10.1103/PhysRevE.96.063303 [24] LOU A Q, WANG H, LI L. A lattice Boltzmann investigation of the saturated pool boiling heat transfer on micro-cavity/fin surfaces[J]. Physics of Fluids, 2023, 35(1): 013316. doi: 10.1063/5.0134043 [25] 陆威, 王婷婷, 徐洪涛, 等. 多孔介质复合方腔双扩散混合对流LBM模拟[J]. 应用数学和力学, 2017, 38(7): 780-793. doi: 10.21656/1000-0887.370175LU Wei, WANG Tingting, XU Hongtao, et al. LBM simulation of double diffusive mixed convection in a porous medium composite cavity[J]. Applied Mathematics and Mechanics, 2017, 38(7): 780-793. (in Chinese) doi: 10.21656/1000-0887.370175 [26] MONDAL K, BHATTACHARYA A. Bubble dynamics and enhancement of pool boiling in presence of an idealized porous medium: a numerical study using lattice Boltzmann method[J]. Journal of Thermal Science and Engineering Applications, 2022, 14(8): 081004. doi: 10.1115/1.4053054 [27] SHI J, FENG D, CHEN Z, et al. Numerical study of a hybrid thermal lattice Boltzmann method for pool boiling heat transfer on a modeled hydrophilic metal foam surface[J]. Applied Thermal Engineering, 2023, 229: 120535. doi: 10.1016/j.applthermaleng.2023.120535 [28] QIN J, XU Z, MA X. Pore-scale simulation on pool boiling eat transfer and bubble dynamics in open-cell metalfoam by lattice Boltzmann method[J]. Journal of Heat Transfer, 2021, 143(1): 011602. doi: 10.1115/1.4048734 [29] GONG S, CHENG P. A lattice Boltzmann method for simulation of liquid-vapor phase-change heat transfer[J]. International Journal of Heat and Mass Transfer, 2012, 55(17/18): 4923-4927. [30] YUAN P, SCHAEFER L. Equations of state in a lattice Boltzmann model[J]. Physics of Fluids, 2006, 18(4): 042101. doi: 10.1063/1.2187070 [31] LI L, CHEN C, MEI R, et al. Conjugate heat and mass transfer in the lattice Boltzmann equation method[J]. Physical Review E, 2014, 89(4): 043308. doi: 10.1103/PhysRevE.89.043308 [32] HU Z, WANG D, XU J, et al. Development of a loop heat pipe with the 3D printed stainless steel wick in the application of thermal management[J]. International Journal of Heat and Mass Transfer, 2020, 161: 120258. doi: 10.1016/j.ijheatmasstransfer.2020.120258 [33] PAVLENKO A N, KUZNETSOV D V, BESSMELTSEV V P. Experimental study on heat transfer and critical heat flux during pool boiling of nitrogen on 3D printed structured copper capillary-porous coatings[J]. Journal of Engineering Thermophysics, 2021, 30: 341-349. doi: 10.1134/S1810232821030012 [34] 胡卓焕, 罗婷, 许佳寅, 等. 毛细芯蒸汽槽道孔径对环路热管(LHP)传热性能影响研究[J]. 热能动力工程, 2022, 37(5): 86-92. https://www.cnki.com.cn/Article/CJFDTOTAL-RNWS202205012.htmHU Zhuohuan, LUO Ting, XU Jiayin, et al. Research on effect of various wick steam groove structures on heat transfer performance of loop heat pipe[J]. Journal of Engineering for Thermal Energy and Power, 2022, 37(5): 86-92. (in Chinese) https://www.cnki.com.cn/Article/CJFDTOTAL-RNWS202205012.htm [35] LOU Q, GUO Z, SHI B. Evaluation of outflow boundary conditions for two-phase lattice Boltzmann equation[J]. Physical Review E, 2013, 87(6): 063301. doi: 10.1103/PhysRevE.87.063301 [36] LIU Z, QIN J, WU Z, et al. Numerical investigation on pool boiling mechanism of hybrid structures with metal foam and square column by LBM[J]. Journal of Thermal Science, 2022, 31(6): 2293-2308. doi: 10.1007/s11630-022-1711-9 [37] KANDLIKAR S G. Scale effects on flow boiling heat transfer in microchannels: a fundamental perspective[J]. International Journal of Thermal Sciences, 2010, 49(7): 1073-1085. doi: 10.1016/j.ijthermalsci.2009.12.016 [38] HUANG R L, ZHAO C Y, XU Z G. Investigation of bubble behavior in gradient porous media under pool boiling conditions[J]. International Journal of Multiphase Flow, 2018, 103: 85-93. doi: 10.1016/j.ijmultiphaseflow.2018.02.005 [39] COLOMBO M, FAIRWEATHER M. Prediction of bubble departure in forced convection boiling: a mechanistic model[J]. International Journal of Heat and Mass Transfer, 2015, 85(1): 135-146. [40] ZHANG H W, WANG K P, Chen Z. Material point method for dynamic analysis of saturated porous media under external contact/impact of solid bodies[J]. Computer Methods in Applied Mechanics and Engineering, 2009, 198(17/20): 1456-1472. [41] SHEN L, SCHMITT D R. Hydro-mechanical modelling of fault movement in response to subsurface fluid injection, a finite element approach[C]//GeoConvention 2016: Optimizing Resources. 2016. [42] KARAKASHEV S I, STOCKELHUBER K W, TSEKOV R, et al. Bubble rubbing on hydrophobic solid surfaces[J]. Colloids and Surfaces A: Physicochemical and Engineering Aspects, 2018, 555: 638-645. doi: 10.1016/j.colsurfa.2018.07.037 [43] VEMURI S, KIM K J. Pool boiling of saturated FC-72 on nano-porous surface[J]. International Communications in Heat and Mass Transfer, 2005, 32(1/2): 27-31. [44] XU Z G, QU Z G, ZHAO C Y, et al. Experimental correlation for pool boiling heat transfer on metallic foam surface and bubble cluster growth behavior on grooved array foam surface[J]. International Journal of Heat and Mass Transfer, 2014, 77: 1169-1182. doi: 10.1016/j.ijheatmasstransfer.2014.06.037 [45] LI C, PETERSON G P, EL-GENK M S. Experimental studies on CHF of pool boiling on horizontal conductive micro porous coated surfaces[J]. American Institute of Physics, 2008, 969: 12-20. [46] OU L W, JIANG X C, ZHANG S W, et al. Pool boiling performance of a sintered aluminum powder wick for a lightweight vapor chamber[J]. Machines, 2023, 11(4): 468. doi: 10.3390/machines11040468 -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号