Design of the Battery Thermal Management System With Phase Change Material Coupled Cold Plates

-

摘要:

以相变材料耦合冷板电池热管理系统为研究对象,采用数值方法研究了系统的冷却性能。结果表明,通过增加耦合系统的冷却水流量可以降低电池组温度和温差,但是显著增加了冷板功耗,系统能效较低。为了提高耦合热管理系统的冷却效率,在固定系统体积的情况下,采用优化策略对系统中相变材料的厚度分布进行调整。典型算例结果表明,优化策略仅需5步调整就能得到最佳相变材料厚度分布。相比于优化前系统,优化后的系统使电池组最高温度降低了1.1 K,温差减小了29%。在同等电池组温差下,优化系统的功耗相比优化前系统下降了64%。

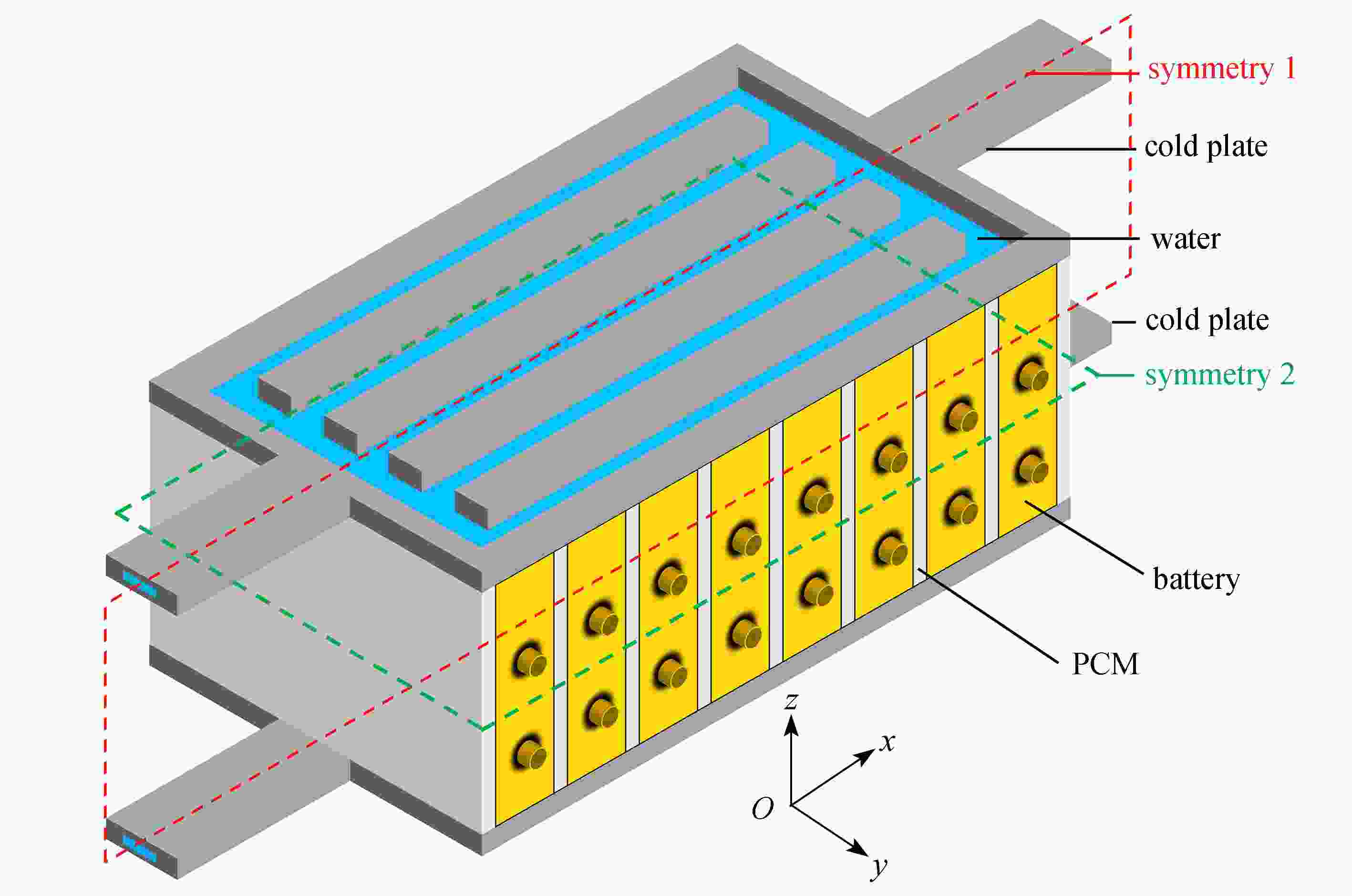

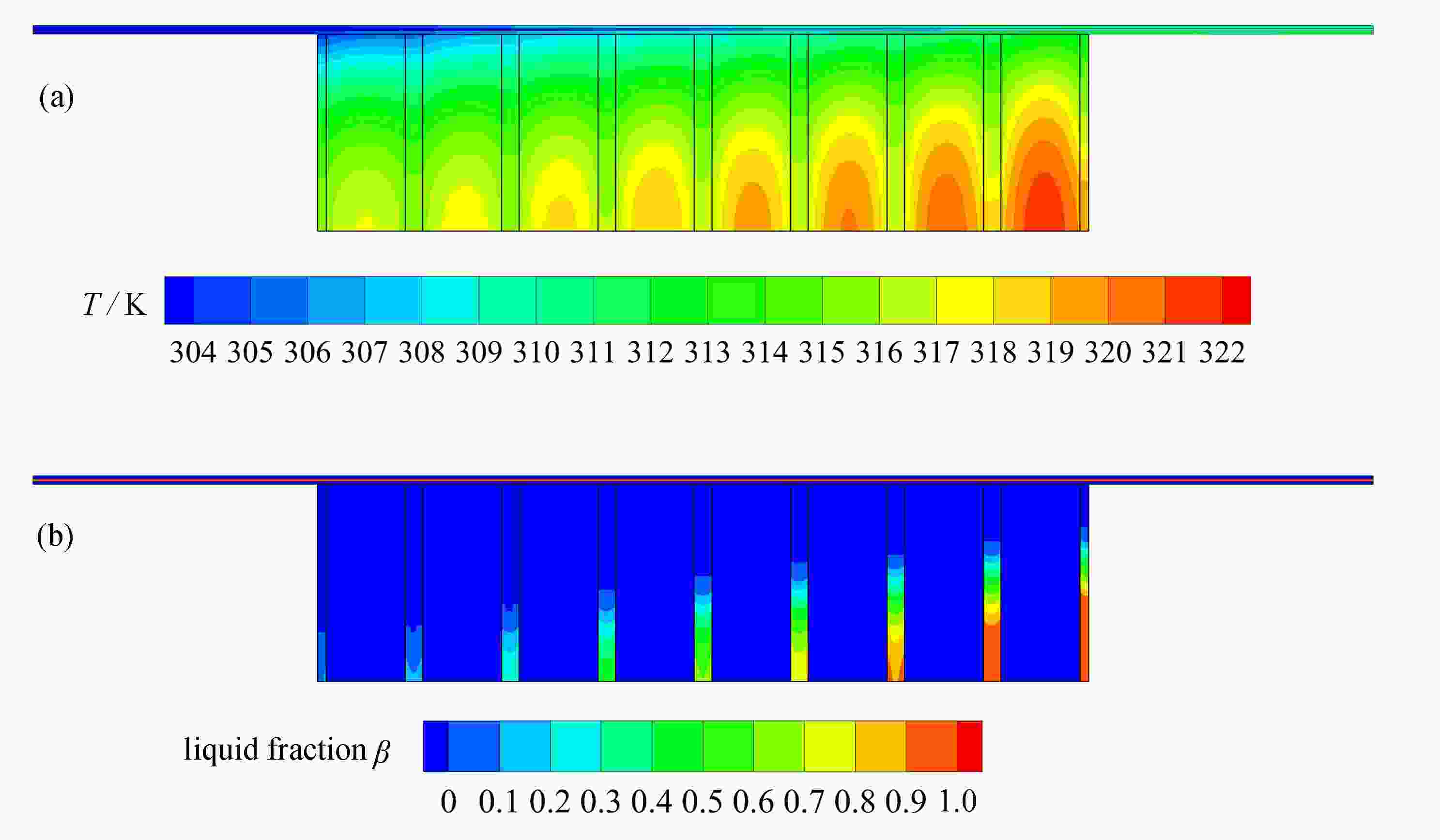

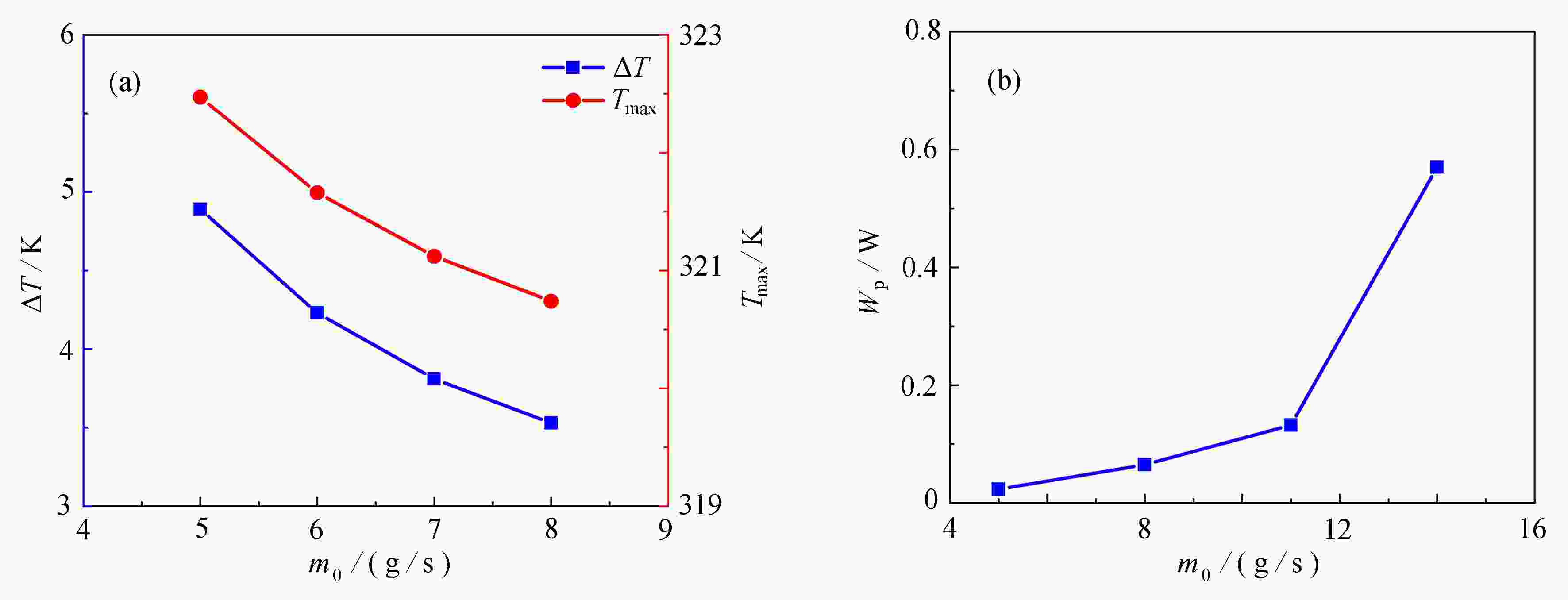

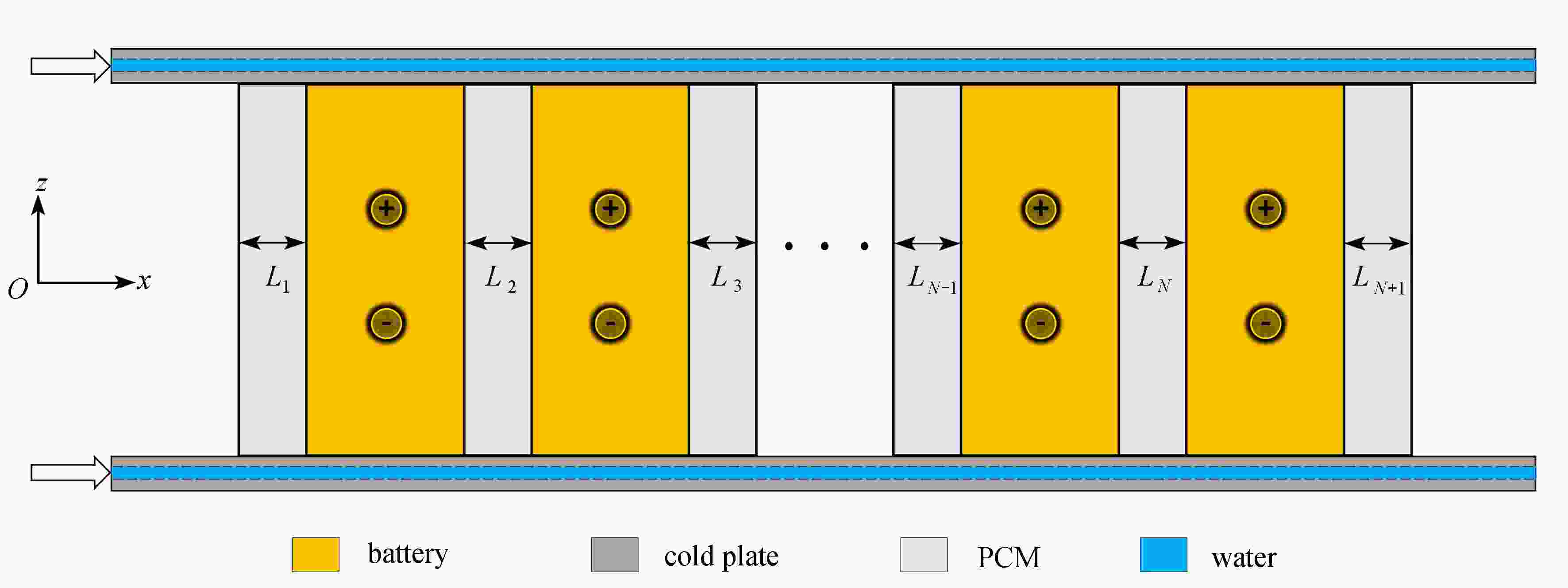

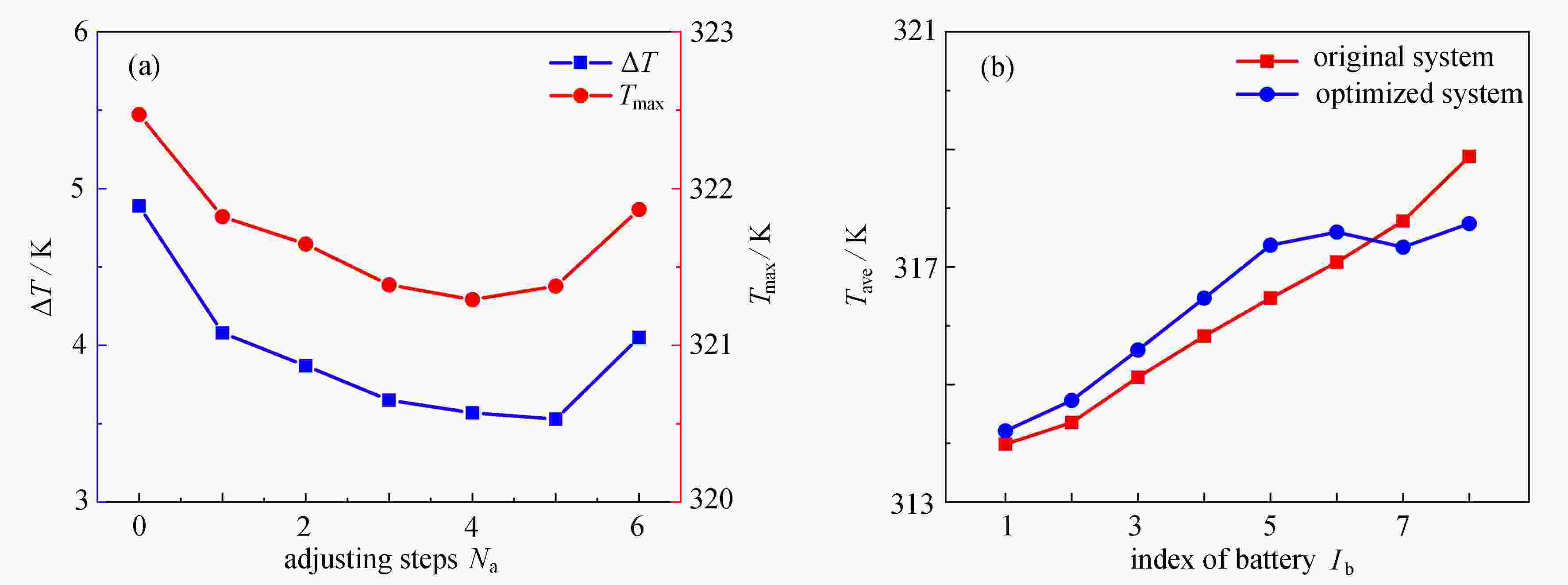

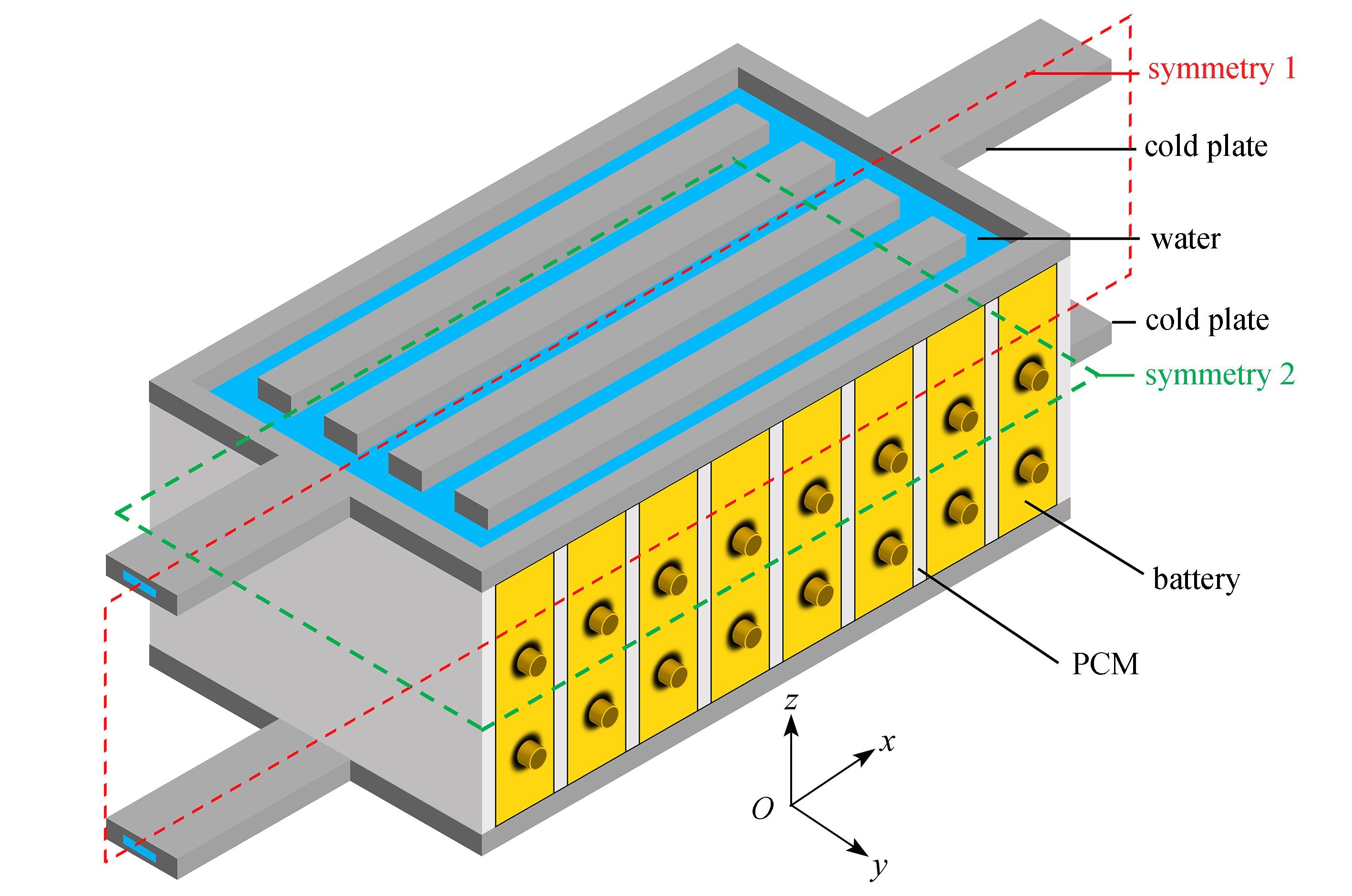

Abstract:The battery thermal management system with phase change material coupled cold plates was investigated with the numerical simulation method. The results show that, the temperature and temperature difference of the battery pack decreases with the increase of the flow rates of the cold plate in the system, while the power consumption of the cold plate significantly increases, which leads to poor efficiency of the system. To improve the efficiency of the coupled thermal management system, an adjusting strategy was introduced to optimize the thickness distribution of phase change materials with the system volume fixed. The optimized results of typical cases show that, the optimal phase change material thickness distribution can be obtained by only 5 adjusting steps. Compared with the original system, the maximum temperature of the battery pack drops by 1.1 K and the temperature difference narrows down by 29% after the optimization. To achieve the same temperature difference in the battery pack, the power consumption of the optimized system lowers down by 64% compared with that of the original system.

-

Key words:

- phase change material /

- cold plate /

- battery thermal management /

- optimization strategy

-

表 1 系统中各种材料物性参数

Table 1. Physical property parameters of various materials in the system

property Al water PCM[19] battery[18-19] density ρ/(kg/m3) 2702 997.56 950 2335 specific heat cp/(J/(kg·K)) 903 4181.72 3000 950 dynamic viscosity η/(kg/(m·s)) − 8.89 × 10-4 − − melting temperature T/K − − 315.15 ~ 317.15 − latent heat Hp/(kJ/kg) − − 141.7 − thermal conductivity λ/(W/(m·K)) 237 0.62 7.654 1.05, 21.1, 21.1 (kx, ky, kz) -

[1] LU L, HAN X, LI J, et al. A review on the key issues for lithium-ion battery management in electric vehicles[J]. Journal of Power Sources, 2013, 226: 272-288. doi: 10.1016/j.jpowsour.2012.10.060 [2] SAECHAN P, DHUCHAKALLAYA I. Numerical investigation of air cooling system for a densely packed battery to enhance the cooling performance through cell arrangement strategy[J]. International Journal of Energy Research, 2021, 49(14): 20670-20684. [3] DING Y, WEI M, LIU R. Channel parameters for the temperature distribution of a battery thermal management system with liquid cooling[J]. Applied Thermal Engineering, 2021, 186: 116494. doi: 10.1016/j.applthermaleng.2020.116494 [4] HUANG Y H, CHENG W L, ZHAO R. Thermal management of Li-ion battery pack with the application of flexible form-stable composite phase change materials[J]. Energy Conversion and Management, 2019, 182: 9-20. doi: 10.1016/j.enconman.2018.12.064 [5] VUDATA S P, BHATTACHARYYA D. Thermal management of a high temperature sodium sulphur battery stack[J]. International Journal of Heat and Mass Transfer, 2021, 181: 122025. doi: 10.1016/j.ijheatmasstransfer.2021.122025 [6] JIANG Z Y, QU Z G. Lithium-ion battery thermal management using heat pipe and phase change material during discharge-charge cycle: a comprehensive numerical study[J]. Applied Energy, 2019, 242: 378-392. doi: 10.1016/j.apenergy.2019.03.043 [7] LING Z Y, WANG F X, FANG X M, et al. A hybrid thermal management system for lithium-ion batteries combining phase change materials with forced-air cooling[J]. Applied Energy, 2015, 148: 403-409. doi: 10.1016/j.apenergy.2015.03.080 [8] SONG L, ZHANG H, YANG C. Thermal analysis of conjugated cooling configurations using phase change material and liquid cooling techniques for a battery module[J]. International Journal of Heat and Mass Transfer, 2019, 133: 827-841. doi: 10.1016/j.ijheatmasstransfer.2018.12.157 [9] 喻寰. 相变材料与液冷耦合的锂电池热管理系统研究[D]. 硕士学位论文. 长沙: 湖南大学, 2019.YU Huan. Study on lithium battery thermal management system based on coupling of phase change materials and liquid cooling[D]. Master Thesis. Changsha: Hunan University, 2019. (in Chinese) [10] CAO J, LUO M, FANG X, et al. Liquid cooling with phase change materials for cylindrical Li-ion batteries: an experimental and numerical study[J]. Energy, 2020, 191: 116565. doi: 10.1016/j.energy.2019.116565 [11] LIU Z, HUANG J, CAO M, et al. Experimental study on the thermal management of batteries based on the coupling of composite phase change materials and liquid cooling[J]. Applied Thermal Engineering, 2021, 185: 116415. doi: 10.1016/j.applthermaleng.2020.116415 [12] BAI F, CHEN M, SONG W, et al. Thermal management performances of PCM/water cooling-plate using for lithium-ion battery module based on non-uniform internal heat source[J]. Applied Thermal Engineering, 2017, 126: 17-27. doi: 10.1016/j.applthermaleng.2017.07.141 [13] ZHU Z, WU X, ZHANG H, et al. Multi-objective optimization of a liquid cooled battery module with collaborative heat dissipation in both axial and radial directions[J]. International Journal of Heat and Mass Transfer, 2020, 155: 119701. doi: 10.1016/j.ijheatmasstransfer.2020.119701 [14] LI J W, ZHANG H Y. Thermal characteristics of power battery module with composite phase change material and external liquid cooling[J]. International Journal of Heat and Mass Transfer, 2020, 156: 119820. doi: 10.1016/j.ijheatmasstransfer.2020.119820 [15] WANG R, LIANG Z, SOURI M, et al. Numerical analysis of lithium-ion battery thermal management system using phase change material assisted by liquid cooling method[J]. International Journal of Heat and Mass Transfer, 2022, 183: 122095. doi: 10.1016/j.ijheatmasstransfer.2021.122095 [16] MOLAEIMANESH G R, MIRFALLAH N S M, DAHMARDEH M. Impact of configuration on the performance of a hybrid thermal management system including phase change material and water-cooling channels for Li-ion batteries[J]. Applied Thermal Engineering, 2020, 181: 116028. doi: 10.1016/j.applthermaleng.2020.116028 [17] CAO J, LING Z, FANG X, et al. Delayed liquid cooling strategy with phase change material to achieve high temperature uniformity of Li-ion battery under high-rate discharge[J]. Journal of Power Sources, 2020, 450: 227673. doi: 10.1016/j.jpowsour.2019.227673 [18] CHEN Y, CHEN K, DONG Y, et al. Bidirectional symmetrical parallel mini-channel cold plate for energy efficient cooling of large battery packs[J]. Energy, 2022, 242: 122553. doi: 10.1016/j.energy.2021.122553 [19] CHEN K, HOU J, SONG M, et al. Design of battery thermal management system based on phase change material and heat pipe[J]. Applied Thermal Engineering, 2021, 188: 116665. doi: 10.1016/j.applthermaleng.2021.116665 [20] CHEN K, CHEN Y, SONG M, et al. Multi-parameter structure design of parallel mini-channel cold plate for battery thermal management[J]. International Journal of Energy Research, 2020, 44(6): 4321-4334. doi: 10.1002/er.5200 [21] 白羽, 方慧灵, 张艳. Oldroyd-B流体绕拉伸楔形体的非稳态滑移流动与传热分析[J]. 应用数学和力学, 2022, 43(3): 272-280BAI Yu, FANG Huiling, ZHANG Yan. Unsteady slip flow and heat transfer analysis of Oldroyd-B fluid over the stretching wedge[J]. Applied Mathematics and Mechanics, 2022, 43(3): 272-280.(in Chinese) [22] WU W, WU W, WANG S. Thermal management optimization of a prismatic battery with shape-stabilized phase change material[J]. International Journal of Heat and Mass Transfer, 2018, 121: 967-977. doi: 10.1016/j.ijheatmasstransfer.2018.01.062 [23] 彭世彬, 郭瑞, 冯上升, 等. 主动冷却点阵夹层防热结构温度响应计算模型[J]. 应用数学和力学, 2022, 43(5): 477-489PENG Shibin, GUO Rui, FENG Shangsheng, et al. A calculation model for temperature responses of active cooling lattice sandwich structures for thermal protection[J]. Applied Mathematics and Mechanics, 2022, 43(5): 477-489.(in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号