Study on Discharge Coefficients of Drain Orifices in Closed Cavities

-

摘要:

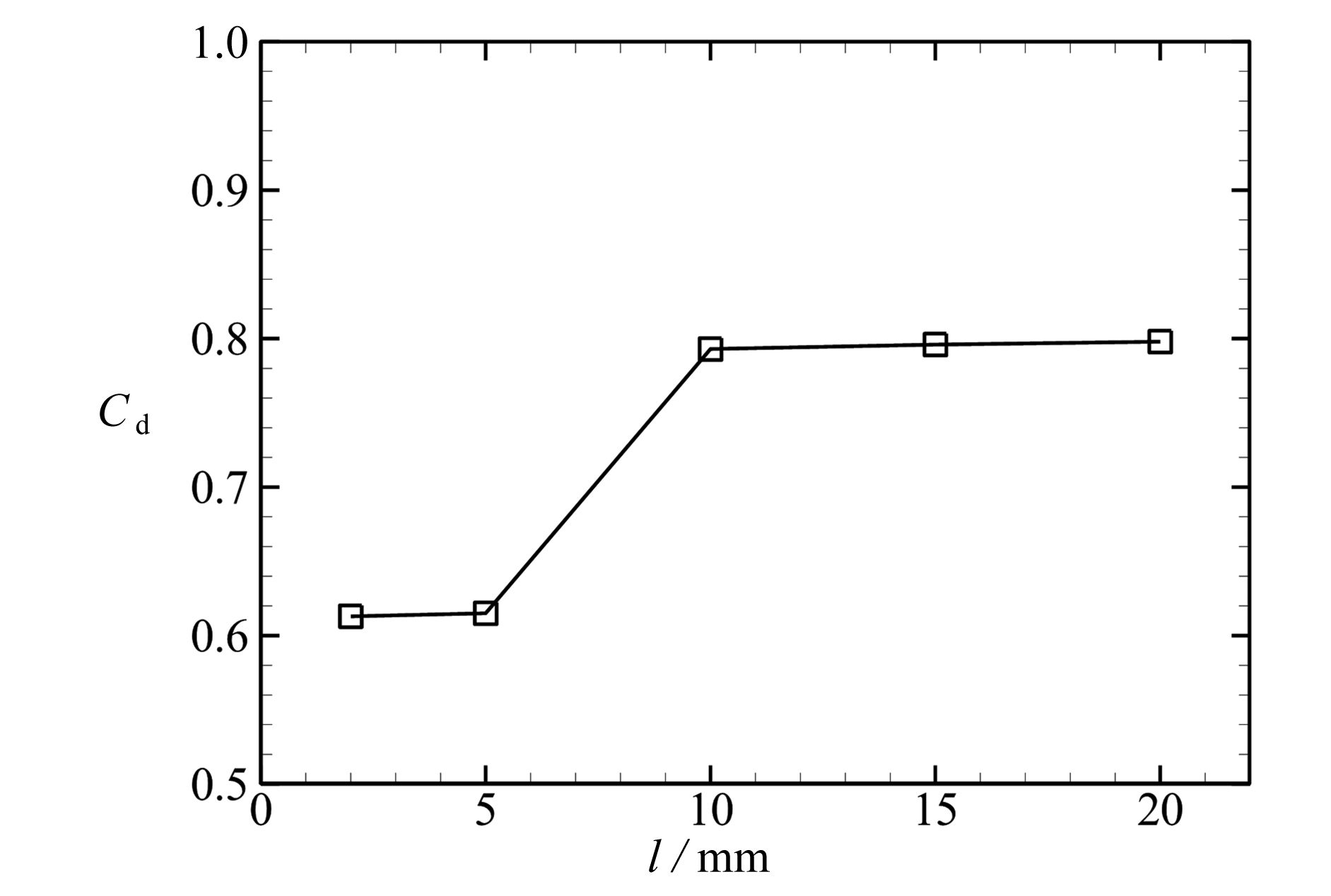

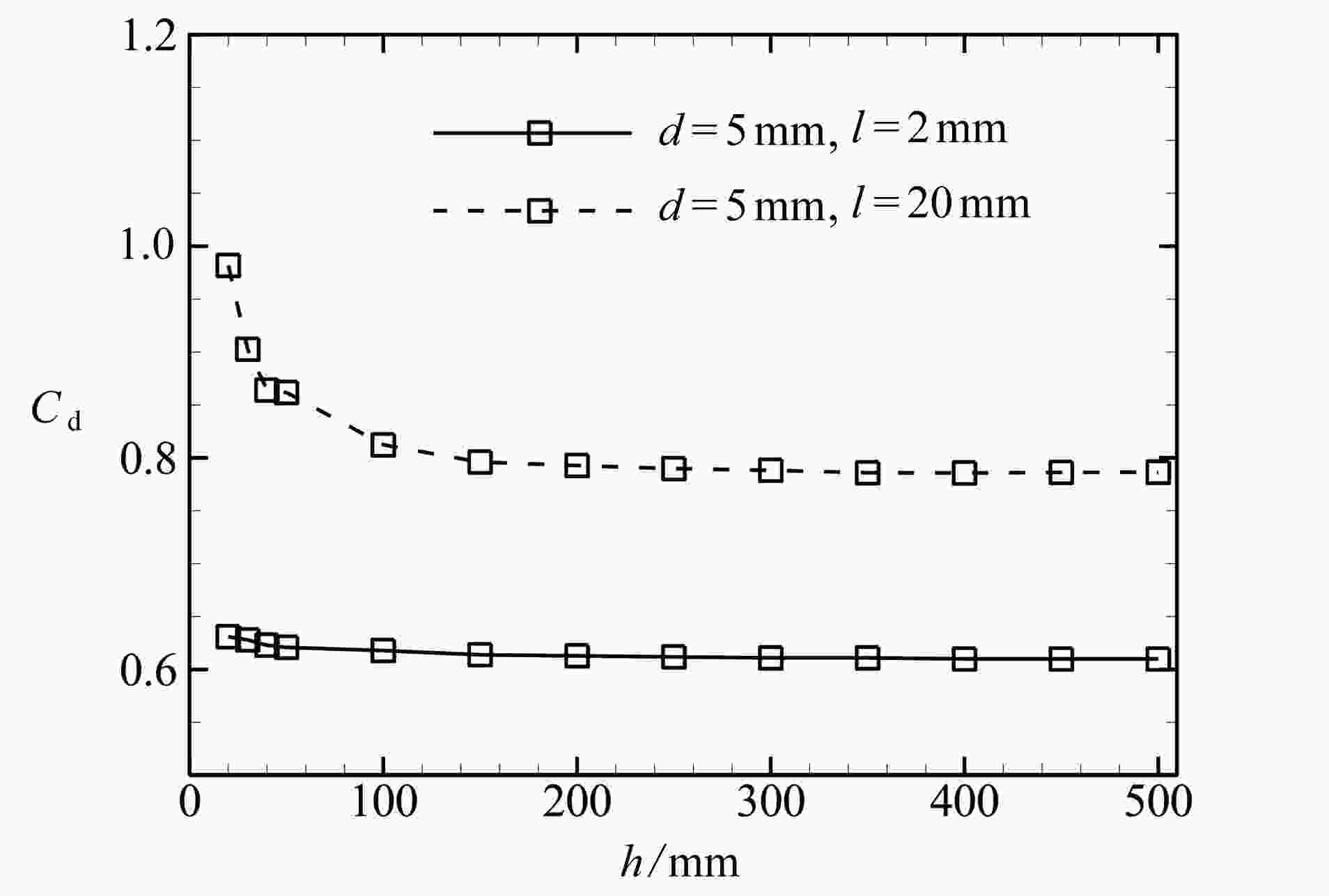

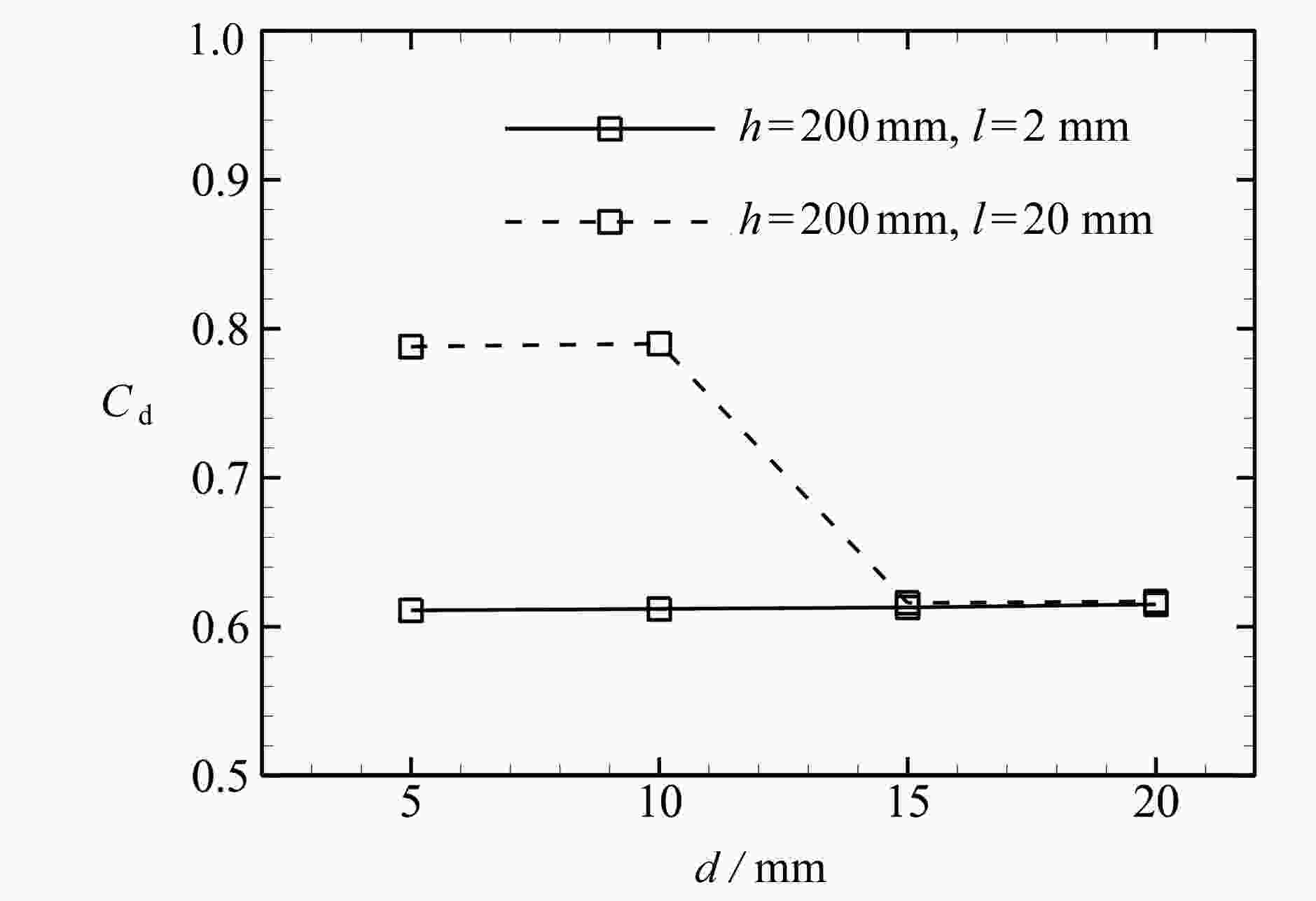

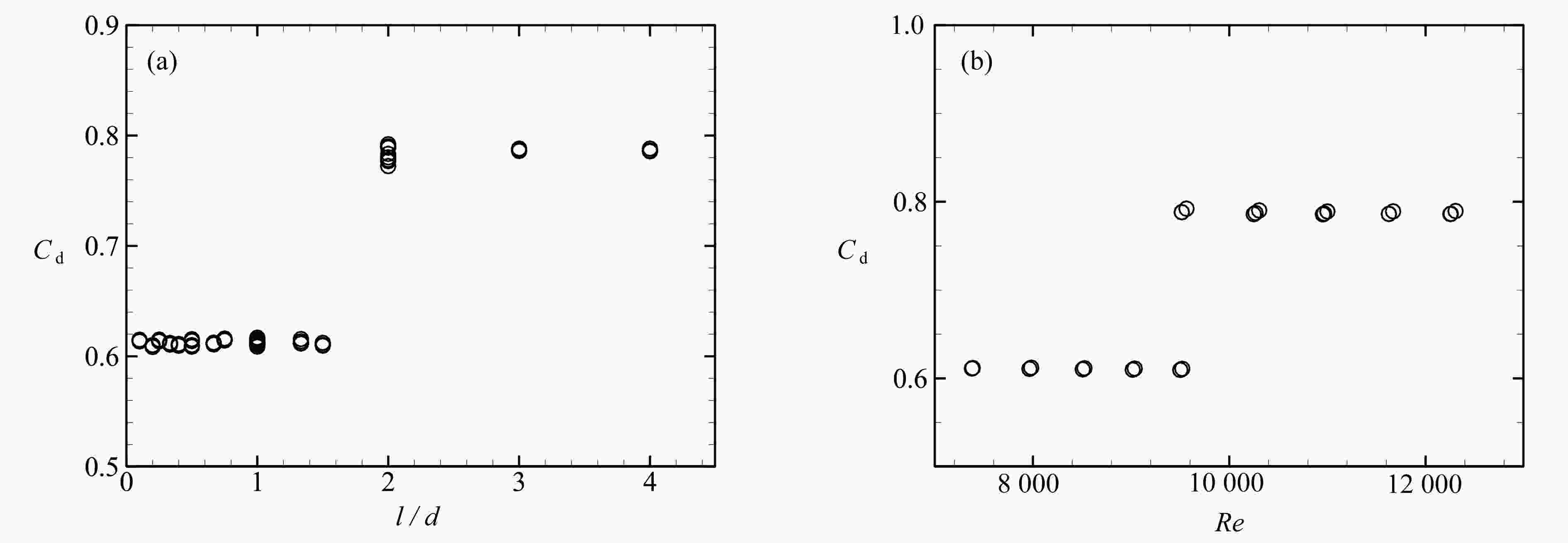

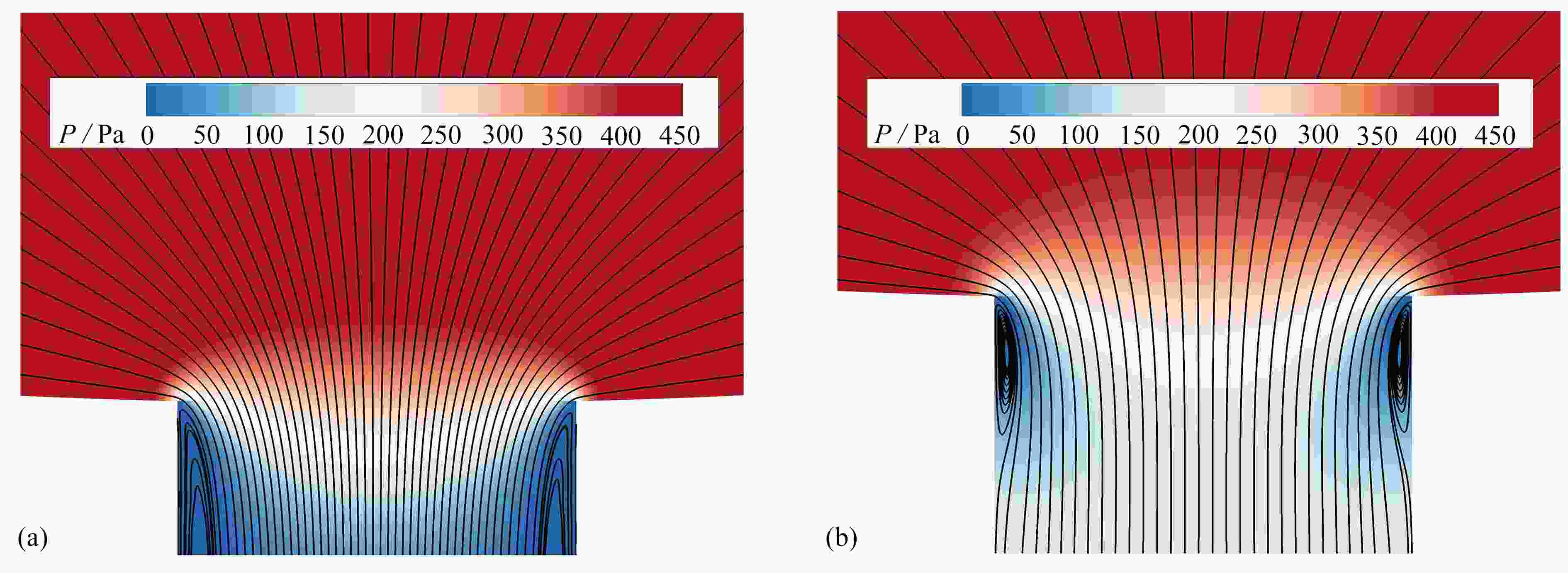

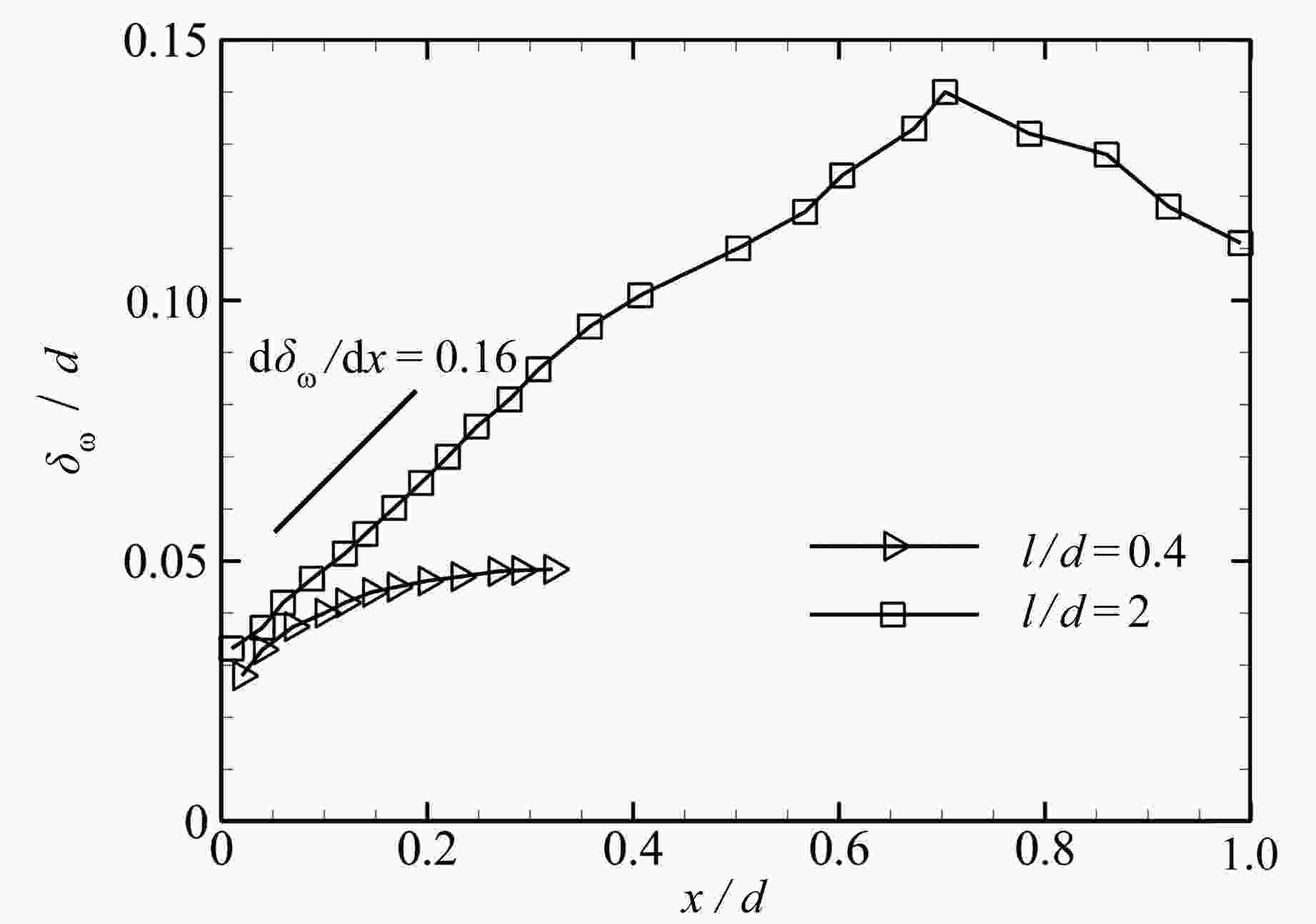

该文利用数值方法模拟了封闭腔体的排液流动,获取了排液孔的流量系数。通过量纲分析法研究了小孔流量系数的主要影响因素,拟合了计算小孔流量系数的经验公式。结果表明:当水头高度小于200 mm时,小孔流量系数随水头高度的增加而减小;当水头高度大于200 mm时,小孔流量系数稳定在0.61附近。不同厚径比的小孔流量系数表现为两种不同的形式:小厚径比的小孔呈现薄孔流动特性,流量系数为0.6左右;大厚径比的小孔呈现厚孔流动特性,流量系数为0.8左右。

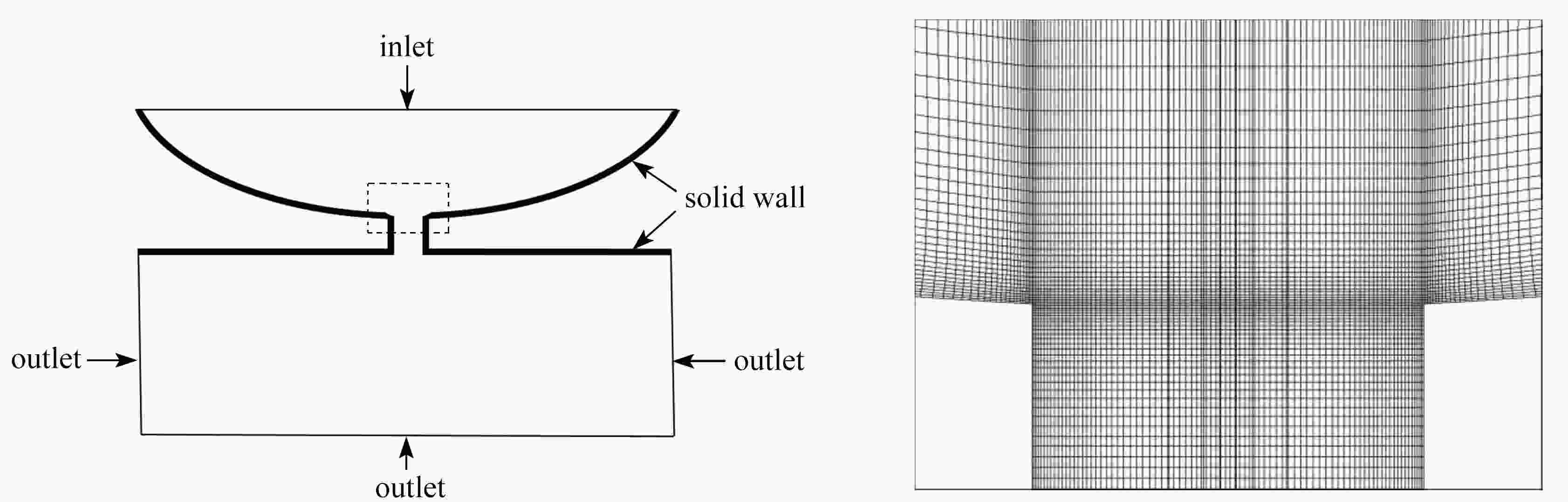

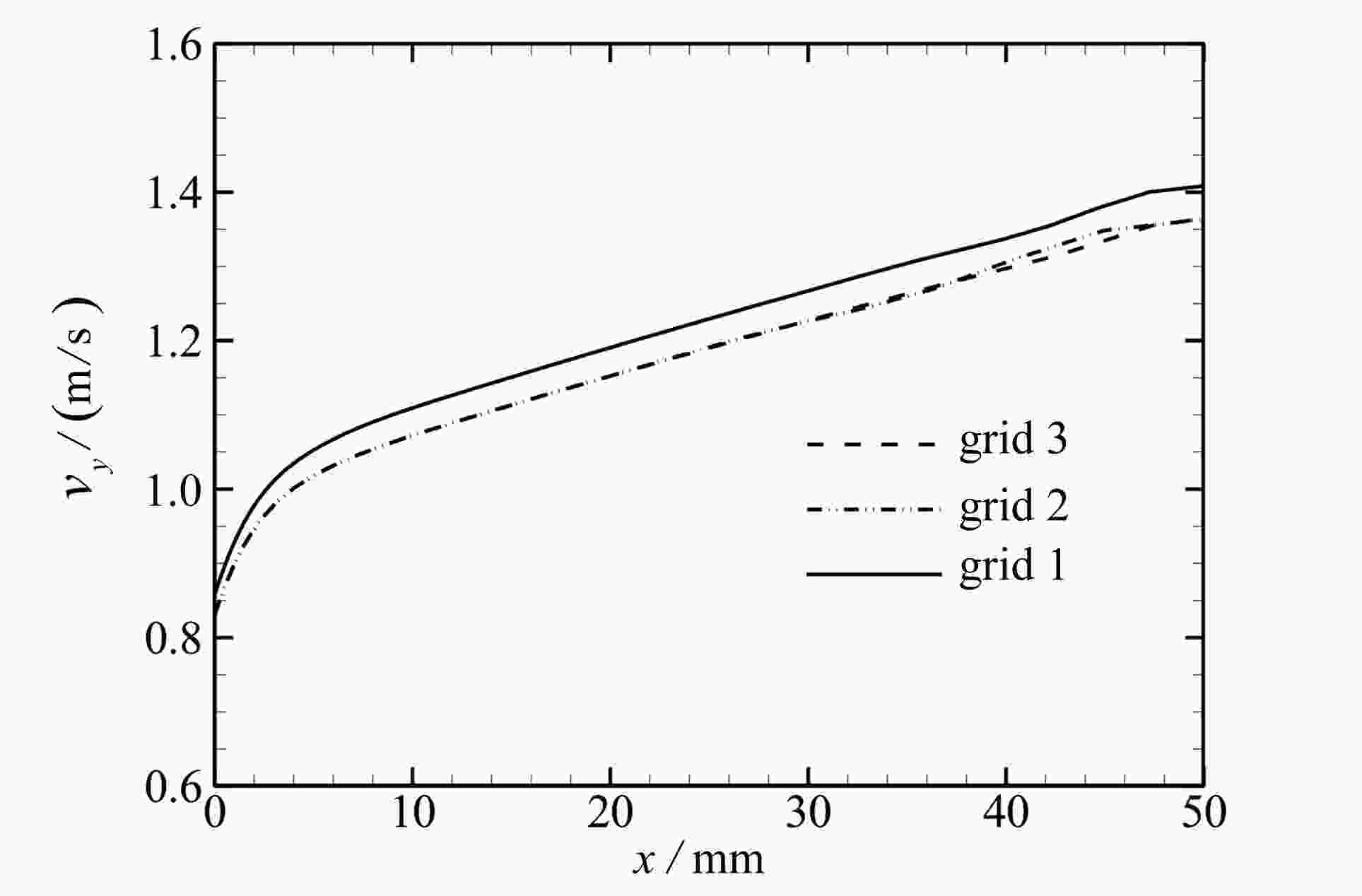

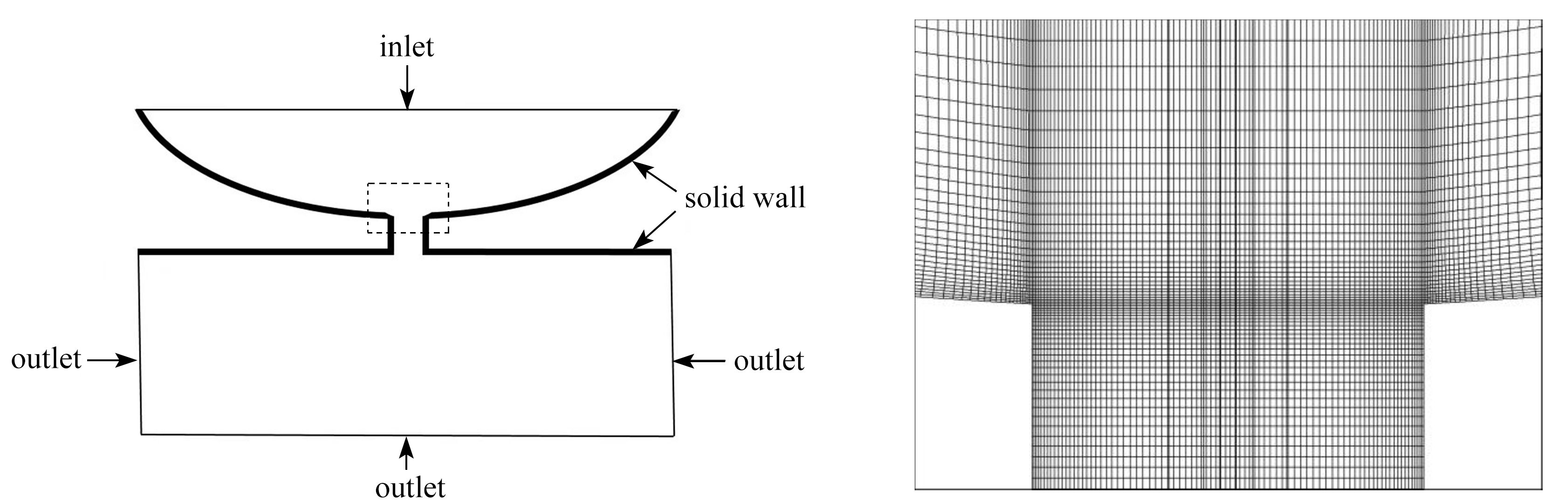

Abstract:The discharge flow was numerically simulated to obtain discharge coefficients. The main factors influencing the discharge coefficients of orifices were studied by dimensional analysis, and the empirical fitting formulas for calculating discharge coefficients were given. The results show that, with a water head height less than 200 mm, the discharge coefficient decreases with the increase of the head height. With a water head height more than 200 mm, the discharge coefficient keeps stable around 0.61. The discharge coefficients with different thickness to diameter ratios show 2 different forms: the orifices with small thickness-diameter ratios show thin orifice flow characteristics, and the discharge coefficient is about 0.6; the orifices with big thickness to diameter ratios show thick orifice flow characteristics, and the discharge coefficient is about 0.8.

-

Key words:

- numerical simulation /

- discharge coefficient /

- dimensional analysis /

- empirical formula

-

表 1 圆形排液孔的几何参数

Table 1. Geometric parameters of circular drain orifices

d/mm l/mm l/d 5 2, 5, 10, 15, 20 0.4, 1, 2, 3, 4 10 2, 5, 10, 15, 20 0.2, 0.5, 1, 1.5, 2 15 2, 5, 10, 15, 20 0.13, 0.3, 0.67, 1, 1.3 20 2, 5, 10, 15, 20 0.1, 0.25, 0.5, 0.75, 1 表 2 数值与试验结果对比

Table 2. Comparison of numerical and experimental results

d/mm h/mm exp[19] num 10 282 0.724 0.746 12.5 267 0.662 0.655 13.5 302 0.651 0.662 16 370 0.633 0.643 -

[1] 聂俊领. 旋转条件下小孔流量系数试验研究与数值分析[D]. 硕士学位论文. 南京: 南京航空航天大学, 2014.NIE Junling. Experimental study and numerical analysis on the discharge coefficient of rotating orifice[D]. Master Thesis. Nanjing: Nanjing University of Aeronautics and Astronautics, 2014. (in Chinese) [2] 吴进军, 常国强, 钱鑫. 鳞片孔形状对冷却效率及流量系数的影响[J]. 现代机械, 2020(1): 64-68WU Jinjun, CHANG Guoqiang, QIAN Xin. Effect of scale hole shape on film cooling efficiency and flow coefficient[J]. Modern Machinery, 2020(1): 64-68.(in Chinese) [3] DING Y W, WEI X H, NIE H, et al. Discharge coefficient calculation method of landing gear shock absorber and its influence on drop dynamics[J]. Journal of Vibroengineering, 2018, 20(7): 2550-2562. doi: 10.21595/jve.2018.19049 [4] 曹睿, 刘艳升, 严超宇, 等. 垂直锐边孔口的自由出流特性(Ⅰ):流动状态和孔结构参数对孔流系数的影响[J]. 化工学报, 2008, 59(9): 2175-2180 doi: 10.3321/j.issn:0438-1157.2008.09.004CAO Rui, LIU Yansheng, YAN Chaoyu, et al. Characteristics of vertical sharp-edged orifice discharge (Ⅰ): effect of flow regime and configuration parameters on orifice discharge coefficient[J]. Journal of Chemical Industry and Engineering, 2008, 59(9): 2175-2180.(in Chinese) doi: 10.3321/j.issn:0438-1157.2008.09.004 [5] 郭成富, 王秀兰, 王勇. 倒(圆)角进口圆孔流量系数的试验研究[J]. 燃气涡轮试验与研究, 1997(4): 10-15GUO Chengfu, WANG Xiulan, WANG Yong. Experimental study on discharge coefficient of round orifice at chamfered inlet[J]. Gas Turbine Experiment and Research, 1997(4): 10-15.(in Chinese) [6] 史维祥, 葛思华. 小孔流量试验研究[J]. 西安交通大学学报, 1966(1): 58-65.SHI Weixiang, GE Sihua. Experimental study on small orifice flow[J] Journal of Xi’an Jiaotong University, 1966(1): 58-65. (in Chinese) [7] WEBSTER G K, COLL G T, KANDULA M, et al. Compressibility effects on the discharge coefficient of small diameter ratio sharp-edged orifices with and without downstream chamfer[C]//AIAA Aviation 2019 Forum. Dallas, Texas, USA, 2019. [8] CHISHOLM D. Two-Phase Flow in Pipelines and Heat Ex-Changers[M]. London: The Institution of Chemical Engineers, 1983. [9] LICHTAROWICZ A, DUGGINS R K, MARKLAND E. Discharge coefficients for incompressible noncavitating flow through long orifices[J]. Journal of Mechanical Engineering Science, 2006, 7(2): 210-219. [10] ABD H M, ALOMAR O R, MOHAMED I A. Effects of varying orifice diameter and Reynolds number on discharge coefficient and wall pressure[J]. Flow Measurement and Instrumentation, 2019, 65: 219-226. doi: 10.1016/j.flowmeasinst.2019.01.004 [11] FU Z F, CUI Z, DAI W H, et al. Discharge coefficient of combined orifice-weir flow[J]. Water, 2018, 10(6): 699-716. doi: 10.3390/w10060699 [12] EGHBALZADEH A, JAVAN M, HAYATI M. Discharge prediction of circular and rectangular side orifices using artificial neural networks[J]. KSCE Journal of Civil Engineering, 2016, 20(2): 990-996. doi: 10.1007/s12205-015-0440-y [13] WERTH D E, KHAN A A, GREGG W B. Experimental study of wall curvature and bypass flow effects on orifice discharge coefficients[J]. Experiments in Fluids, 2005, 39(3): 485-491. doi: 10.1007/s00348-005-0939-y [14] 黄一帆, 娄钦. T型微通道内的幂律流体液滴破裂行为的格子Boltzmann方法模拟[J]. 应用数学和力学, 2020, 41(10): 1125-1145HUANG Yifan, LOU Qin. Power-law fluid droplet dynamic behaviors in T-junction micro-channels with the lattice Boltzmann method[J]. Applied Mathematics and Mechanics, 2020, 41(10): 1125-1145.(in Chinese) [15] 王金城, 关晖, 卫志军, 等. 壁面结构对三维可压缩气泡群影响的数值模拟研究[J]. 应用数学和力学, 2022, 43(1): 49-62WANG Jincheng, GUAN Hui, WEI Zhijun, et al. Numerical analysis on effects of wall structures on bubble groups[J]. Applied Mathematics and Mechanics, 2022, 43(1): 49-62.(in Chinese) [16] 尹强, 齐晓霓, 梁伟. 二元海水液滴对心碰撞过程数值模拟[J]. 应用数学和力学, 2020, 41(3): 268-279YIN Qiang, QI Xiaoni, LIANG Wei. Numerical simulation of head-on binary collision between seawater droplets[J]. Applied Mathematics and Mechanics, 2020, 41(3): 268-279.(in Chinese) [17] SHIH T H, LIOU W W, SHABBIR A, et al. A new k-ɛ eddy viscosity model for high Reynolds number turbulent flows[J]. Computers & Fluids, 1995, 24(3): 227-238. [18] 金朝铭. 液压流体力学[M]. 北京: 国防工业出版社, 1994.JIN Chaoming. Hydraulic Fluid Mechanics[M]. Beijing: National Defense Industry Press, 1994. (in Chinese) [19] JAN C D, NGUYEN Q T. Discharge coefficient for a water flow through a bottom orifice of a conical hopper[J]. Journal of Irrigation & Drainage Engineering, 2010, 136(8): 567-572. [20] 王哲. GJB5431—2005《飞机结构防水和排水设计要求》研究[J]. 航空标准化与质量, 2013(2): 41-42 doi: 10.3969/j.issn.1003-6660.2013.02.012WANG Zhe. GJB5431—2005 Study on Design Requirements for Waterproof and Drainage of Aircraft Structures[J]. Aeronautic Standardization & Quality, 2013(2): 41-42.(in Chinese) doi: 10.3969/j.issn.1003-6660.2013.02.012 [21] 许常悦, 郑静, 王哲, 等. 方柱跨声速流动中的剪切层和尾迹特性[J]. 上海交通大学学报, 2021, 55(4): 403-411XU Changyue, ZHENG Jing, WANG Zhe, et al. Shear layer and wake characteristics of square cylinder in transonic flow[J]. Journal of Shanghai Jiaotong University, 2021, 55(4): 403-411.(in Chinese) -

下载:

下载:

渝公网安备50010802005915号

渝公网安备50010802005915号